Silico® Linear Silicone Fluids

Polydimethylsiloxane (PDMS)

| Grade Name | Viscosity Range (cSt) | Description |

| ULV Ultra-Low Viscosity | 0.65 – 1 cSt | Extremely low viscosity, water-like flow; ideal for high-penetration applications |

| LV-A Low Viscosity A | 5 – 20 | High fluidity; suitable for spray cosmetics, lubricants |

| LV-B Low Viscosity B | 50 – 100 | For gloss, water resistance, and fabric care; balances flow and durability; ideal for personal care use. |

| SV-A Standard Viscosity A | 200 – 500 | For mold release agents, silicone oil additives with moderate flow |

| SV-B Standard Viscosity B | 800 – 1,000 | General-purpose silicone oil for industrial formulations |

| SV-C Standard Viscosity C | 3,000 – 5,000 | Used in lubrication, heat transfer, coatings, eye surgery, textiles, and personal care products. |

| HV-A High Viscosity A | 10,000 – 30,000 | Thick texture; used for structural additives or viscosity modification |

| HV-B High Viscosity B | 50,000 – 100,000 | Paste-like feel; ideal for sealants and potting compounds |

| UHV-A Ultra-High Viscosity A | 300,000 – 800,000 | Non-flowing, excellent stringiness; used in high-performance sealants |

| UHV-B Ultra-High Viscosity B | 1,000,000 – 2,500,000 | Maximum consistency; for structural adhesives and tacky sealing systems |

| >> Polydimethylsiloxane(PDMS) | ||

Phenyl Silicone Fluids

| CAS NO. | Product Name | Typical Viscosity |

| 70131-69-0 | PC19816 Phenyl-Modified polymethylphenylsiloxane | 15 – 30 cSt |

| 70131-69-0 | PC19826 Phenyl Trimethicone | 10 – 50 cSt |

| 63148-52-7 | PF8250 Polyphenylmethyl dimethylsiloxane | 25 – 40 cSt |

| 63148-52-7 | PF8255 polyphenylmethylpoly dimethylsiloxane | 500 – 1000 cSt |

| 63148-58-3 | PF8260 Polymethylphenylsiloxane | 50–500 cSt |

| 3982-82-9 | PF8704 Silicone Diffusion Pump Fluid | 36 – 44 cSt |

| 3982-82-9 | PF8705 Silicone Diffusion Pump Fluid | 40 – 50 cSt |

| 68037-54-7 | PF9181 Methyl Phenyl Cyclosiloxane | 500 cSt |

| 68083-14-7 | DP801 Polydiphenylsiloxane Fluid | 100 – 500 cSt |

| 9005-12-3 | PM901 Phenyl-Modified Polymethylsiloxane | 350 – 1000 cSt |

| >> Other Phenyl Silicone Fluids | ||

Alkyl Alkoxy Modified Silicones Fluid

| CAS NO. | Product Name | Typical Viscosity |

| N/A | PC12503 Cosmetics Grade Silicon Wax | 30-70 cSt (37°C) |

| N/A | PC12636 Silicone Wax for Skin Conditioning | N/A |

| N/A | PC12691 Alkyl Modified Dimethicone for Cosmetics | N/A |

| N/A | PC12701 Alkyl Modified Dimethicone for Personal Care | 0.900-0.940 cSt |

| N/A | PC12711 Alkyl Modified Dimethicone for Cosmetics | 0.920-0.970 cSt |

| 142982-20-5 | PF2110 Low Viscosity Silicone Fluid | <10 cSt |

| N/A | SF0203 Alkyl-Aryl Functional Silicone Fluid | 1400 – 1800 cSt |

| N/A | SF0206 Long Chain Alkyl Functional Silicone Fluid | 900 – 1500 cSt |

| N/A | SF0202 Alkyl-Aryl Functional Silicone Fluid | 1200 – 1400 cSt |

| >> Other Alkyl Alkoxy Modified Silicone Fluids | ||

Fluoro-Modified PDMS

| CAS NO. | Product Name | Typical Viscosity |

| 63148-56-1 | FF9020 Fluorosilicone Fluid | 300 – 1,000 cSt |

| 63148-56-1 | FF9020 Fluorosilicone Fluid | 10,000 – 13,000 cSt |

| 68607-77-2 | FS8012 Hydroxyl-Terminated Fluorosilicone Fluid | 500–2,000 cSt |

| 68951-98-4 | FV4012 Vinyl-Terminated Fluorosilicone Fluid | 1,000 – 5,000 cSt |

| 68952-30-7 | FH20789 Hydride-Terminated Fluorosilicone Fluid | 100 – 1,000 cSt |

| N / A | FE Series Polyether-Modified Fluorosilicone Fluids | 300 – 2,500 cSt |

| >> Other Fluorosilicone Fluids | ||

Vinyl Silicone Fluids (1)

| CAS NO. | Product Name | Typical Viscosity |

| 68083-19-2 | V401 Vinyl Silicone Oil (Linear Type) | 10 – 10,000 cSt |

Silico® Functional Silicone Fluids

Hydroxy (–OH) Terminated PDMS

| CAS NO. | Product Name | Typical Viscosity |

| 70131-67-8 | OH-500 Hydroxy-Terminated Polydimethylsiloxane (PDMS) | 100 – 100,000 cSt |

| 67923-19-7 | OH-72 Hydroxypropyl-Terminated Polydimethoxysiloxane | 15 – 100 cSt |

| 80801-30-5 | OH-78 Hydroxy-Terminated Methyl Phenyl Silicone Fluid | 100 – 500 cSt |

| 104780-66-7 | OH-80 Hydroxypropyl-Terminated Polydimethoxysiloxane | By molecular weight |

| 68607-77-2 | OH-81 Hydroxy-Terminated Fluorosilicone Fluid | 80 – 100,000 cSt |

| 63148-52-7 | OH-82 Hydroxy-terminated polymethylphenyl siloxane | 50 – 1,000 cSt cSt |

| 63148-57-2 | OH-85 Hydroxy-terminated polymethylhydrogen siloxane | 15 – 40 cSt |

| 63148-56-1 | OH-86 Hydroxy-terminated polymethyltrifluoro propylsiloxane | 10-50 cSt |

| 63148-58-3 | OH-88 Hydroxy-terminated polymethylamino siloxane | By molecular weight |

| >> Other Hydroxy Silicone Fluids | ||

Amino (–NH₂ / –NH–) Modified Silicone Fluids

| CAS NO. | Amino Silicone Fluids Product | Amine Value (mmol/g) |

| 67923-07-3 | Silico® N6152 Amino Silicone Mold Release Fluid | ~7 mL |

| 99363-37-8 | Silico® N6156 Amine Functional Silicone Fluid | ~49 |

| 63148-62-0 | Silico®-N322 Amino Silicone Fluid ≥500 cSt | 0.50–0.56 |

| 63148-62-0 | Silico®-N323 Amino Silicone Fluid 20~100 cSt | 0.9-1 |

| 63148-62-0 | Silico®-N322D2 Amino Silicone Fluid 200~1000 cSt | 0.2-0.3 |

| 63148-62-0 | Silico®N-Amino-Modified Silicone Fluid 5~20 cSt | 0.5-0.8 |

| >> Other Amino Silicone Fluids | ||

Epoxy (–CH(O)CH₂) Modified Silicone Fluids

| CAS NO. | Product Name | Epoxy Content |

| 102782-97-8 | EF9409 – Epoxypropoxypropyl -Terminated PDMS (140 – 510 cSt) | 0.015 – 0.033 (eq/100g) |

| 102782-97-8 | EF 9413 Epoxycyclohexylethyl-Terminated PDMS (25–1,200 cSt) | 1.9–2.0 (eq/kg) |

| 68952-47-4 / 70131-67-8 | EF 9343 Side-Chain Epoxy-Modified Silicone Fluid (50 – 2,000 cSt) | 0.1 – 1.5 (eq/100g) |

| Proprietary | EF 9682 Epoxy-Functional Silicone Fluid (38 cSt) | ~1,100 g/eq |

| Proprietary | E701 Epoxy-Modified Silicone Oil (50 – 500 cSt) | ≥0.07 (eq/100g) |

| Proprietary | ETE301 Polyether-Epoxy Co-Modified Silicone Oil (≥ 300 cSt) | ≥ 0.03 (eq/100g) |

| Proprietary | ETE301H Polyether-Epoxy Co-Modified Silicone Oil (700-1,000 cSt) | ≥ 1.55-1.9 (eq/kg) |

| Proprietary | ETE302G-2 Polyether-Epoxy Co-Modified Silicone Oil (2,500-3,500 cSt) | 0.017-0.024 (eq/100g) |

| Proprietary | ETE302G2-T Polyether Epoxy Modified Silicone Oil (2,500-3,500 cSt) | 0.017-0.024 (eq/100g) |

Carboxyl (–COOH) Modified Silicone Fluids

| CAS No. | Product Name | Viscosity (25°C) |

| 851486-70-9 | CYS-101 Carboxy-Terminated Silicone Fluid | Not specified |

| 58130-04-4 | CYS-B12 Carboxydecyl-Terminated PDMS | 15 – 30 cSt |

| 58130-04-4 | CYS-B13 Hydroxy-Carboxy-Terminated PDMS | 30 – 50 cSt |

| N / A | CYS-3701E Carboxy-Modified Silicone Fluid | 2,000 cSt |

| >> Other Carboxyl Modified Silicone | ||

Hydrogen (–Si–H) Silicone Fluids

| CAS No. | Product Name | Viscosity (25°C) |

| 63148-57-2 | Silico® HF2020 Methyl Hydrogen Silicone Fluid | 20 – 30 |

| 70900-21-9 | Silico® HF2030 Hydride-Terminated Silicone Fluid | 30 – 1000 |

| 68037-59-2 | Silico® HF2050 Trimethylsilyl-Terminated Silicone Fluid | 12 – 100,000 |

| 69013-23-6 | Silico® HF2060 Hydride-Terminated Silicone Copolymer | 24 – 60 cSt |

| 68952-30-7 | Silico® HF2078 Hydride-Terminated Silicone luid | 1000 – 4000 |

| Not specified | Silico® HF2039 | Hydride-Terminated Poly Siloxane Fluid | 1000 – 4000 |

| >> Other Hydrogen Silicone Fluids | ||

Vinyl (–CH=CH₂) Terminated PDMS

| CAS NO. | Product Name | Typical Viscosity |

| 67762-94-1 | PV401 Phenyl Vinyl Silicone Oil | 500-2500 cSt |

| 68083-19-2 | V402 Vinyl Silicone Oil | 600 cSt |

| 63148-62-9 | V411 Vinyl Silicone Oil (Branched Type) | 1,000 – 10,000 cSt |

| 68083-19-2 | V421 Vinyl Silicone Oil (Linear and Branched Type) | 180 – 1300 cSt |

| N/A | V4011 Vinyl Silicone Oil Emulsion | 180 – 1300 cSt |

| 68083-19-2 | PV501 Vinyl-Terminated Polymethylvinylsiloxane | 800 – 3500 cSt |

| 63148-57-2 | V4011 Vinyl Silicone Oil Emulsion | 50 – 200 cSt |

| >> Other Vinyl Silicone Oils | ||

Mercapto (–SH) Silicone Fluids

| CAS No. | Product Name | Thiol content |

| Proprietary | SC-367 Mercapto Silicone Fluid | SH-Functional | 5.4% (by weight) |

| Proprietary | SC-71-SS Mercapto Silicone Fluid | Low SH | 1.0% (by weight) |

| Proprietary | SC-800 Mercapto Functional Silicone Fluid | 2% (by weight) |

| Proprietary | SC-710 Mercapto Functional Silicone Fluid | 0.28% (by weight) |

| 101810-99-5 / 102783-03-9 |

SC-SiF2060 Mercapto Silicone Fluid | 0.28% (by weight) |

| 102783-03-9 | SMS Series Mercapto Silicone Fluids | 2-17% (by weight) |

| 308072-58-4 | Mercaptopropyl-Terminated Polydimethylsiloxane | Terminal thiol groups |

| >> Other Mercapto Functional Silicone Fluids | ||

Polyether (-PEG/PPG) Modified Silicone Fluids

| CAS NO. | Product Name | Typical Viscosity |

| 67762-85-0 | SH-633 Polyether Modified Silicone Fluids | 800 – 1,200 cSt |

| 68937-55-3 | SH-204 Polyether Modified Silicone Fluids | 300 – 700 cSt |

| 68937-55-3 | SH-204 A Polyether Modified Silicone Fluids | 1,000 – 3,500 cSt |

| N / A | MSD-193 Polyether Modified Silicone Oil | 200 – 700 cSt |

| N / A | SM-9102 Polyether Silicone Fluid | 100 – 10,000 cSt |

| N / A | ST-8013 Fluorinated Polyether Silicone Fluid | 400 – 1,000 cSt |

| N / A | SM-5001 Polyether Silicone Fluid | 200 – 8,000 cSt |

| N / A | SM-5001 Polyether Silicone Fluid | 300 – 6,000 cSt |

| >> Other Polyether Modified Silicone Fluids | ||

Quaternary (–N⁺(CH₃)₃Cl⁻) Silicone Fluids

| CAS NO. | Product Name | Typical Viscosity |

| 134737-05-6 | SQ-80 Quaternary Ammonium Silicone Fluid | 500–900cSt |

Silico® Silicone Fluids – Professional Silicone Fluids Manufacturer in China

Silico® is a globally recognized manufacturer specializing in the research, development, and production of premium-grade silicone fluids. With advanced facilities and a commitment to innovation, we deliver high-purity linear and functional silicone fluids engineered to meet the exacting demands of modern industries.

Trusted Silicone Fluid Solutions for Diverse Applications

Silico® offers a comprehensive portfolio of silicone-based fluids with viscosities ranging from 0.65 to 1,000,000 mm²/s, designed to perform in extreme temperature environments (–60°C to +300°C) and under thermal oxidative stress, UV exposure, and radiation.

We provide both standard dimethylsilicone fluids and customized functional silicone fluids modified with reactive groups (e.g., hydroxyl, amino, epoxy) for enhanced compatibility and crosslinking in specialized systems.

Key Features of Silico® Silicone Fluids

-

Wide temperature stability: –60°C to +300°C

-

Excellent thermal and oxidative resistance

-

Low volatility and surface tension

-

Hydrophobic or hydrophilic surface properties

-

Non-toxic, transparent, and environmentally safe formulations

-

Available in both standard and modified grades

Applications of Silicone Fluids

Silico® silicone fluids are trusted by manufacturers and formulators worldwide in sectors such as:

Electronics and electrical insulation (dielectric fluids, transformer oils)

Automotive and aerospace (lubricants, damping fluids, heat transfer oils)

Textiles and industrial coatings (softeners, water repellents)

Pharmaceutical and personal care (cosmetic-grade silicone oils)

Digital printing and release coatings (anti-stick and leveling agents)

About Silicone Fluids

Chemical Structure

Silicone Fluid, mainly polydimethylsiloxane (PDMS), has the structure [–Si(CH₃)₂–O–]ₙ. Its siloxane backbone with methyl side groups provides high flexibility, thermal stability, and low surface tension—key to silicone fluid's lubricating, insulating, and hydrophobic properties.

Physical Properties

Silicone fluid features low viscosity-temperature coefficient, excellent thermal stability, wide operating temperature range (−60°C to 250°C), low surface tension, high dielectric strength, and strong water repellency. These properties make it ideal for lubrication, insulation, and defoaming applications.

About Silicone Fluids FAQs

Silicone fluid is used in a wide range of industries for lubrication, thermal insulation, dielectric cooling, antifoaming, and cosmetic formulations, due to its high thermal stability and low surface tension.

Yes. High-purity grades of silicone fluid are non-toxic, chemically inert, and biocompatible, making them suitable for use in cosmetics, pharmaceuticals, and medical devices.

Silicone fluids offer exceptional thermal stability, typically functioning between −60°C to +250°C. Specialty grades can tolerate even higher temperatures without decomposition.

Silicone fluid is strongly hydrophobic and insoluble in water, making it ideal for water-repellent coatings, release agents, and foam control in aqueous systems.

Compared to mineral oil, silicone fluid provides better temperature resistance, oxidation stability, dielectric strength, and longevity, especially in demanding or high-performance environments.

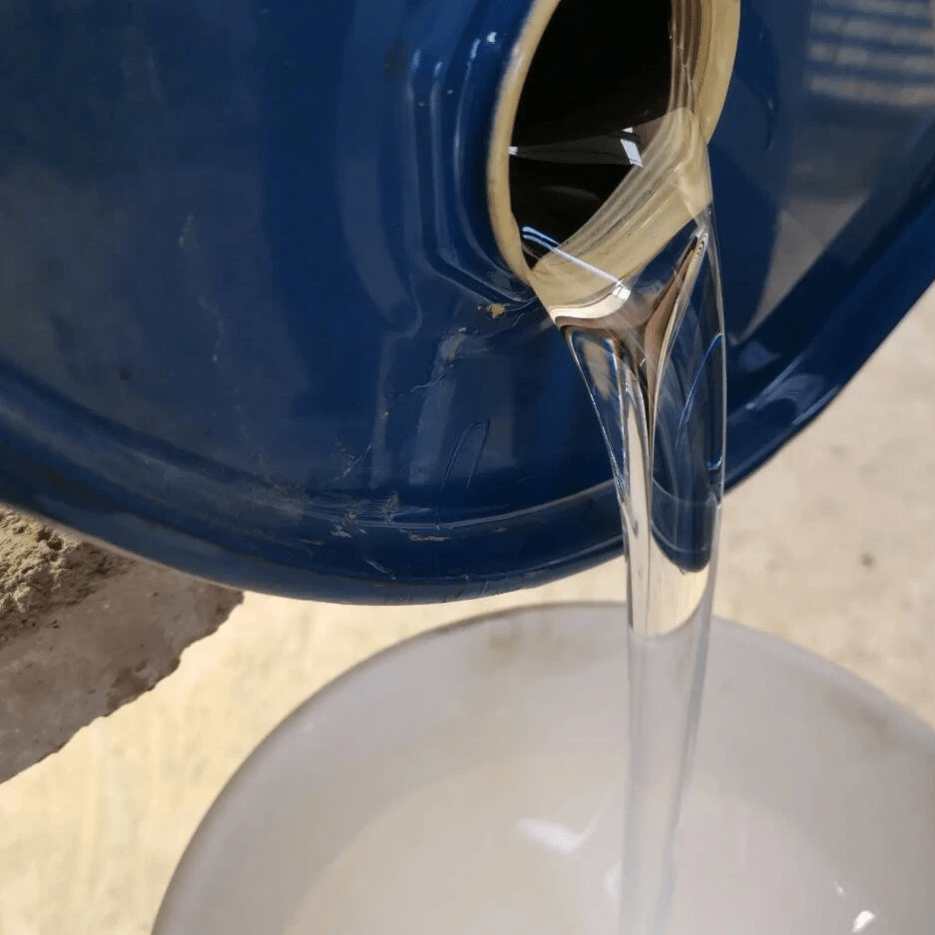

Packaging Specifications

Silico® Prouducts

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

How to Choose the Right Silicone Fluid?

Choosing the right silicone fluid depends on your application’s specific performance needs. Key factors include:

Viscosity: Low-viscosity silicone fluids are ideal for lubrication and heat transfer, while higher viscosities suit damping, sealing, or dielectric use.

Thermal Stability: Ensure the fluid can handle your temperature range. Methyl or phenyl-modified fluids offer stability from −60°C to 250°C or more.

Chemical Compatibility: Select fluids that are inert and non-reactive with other system components to prevent degradation or cross-reactions.

Application-Specific Properties: Use high dielectric strength silicone for electronics, hydrophobic types for coatings, or medical-grade fluids for biocompatibility.

Consult technical datasheets to match fluid properties with performance needs.

Silico® silicone fluids offer reliable solutions across industries—engineered for consistency, safety, and performance.