Vinyl Silanes

Vinyl Silanes

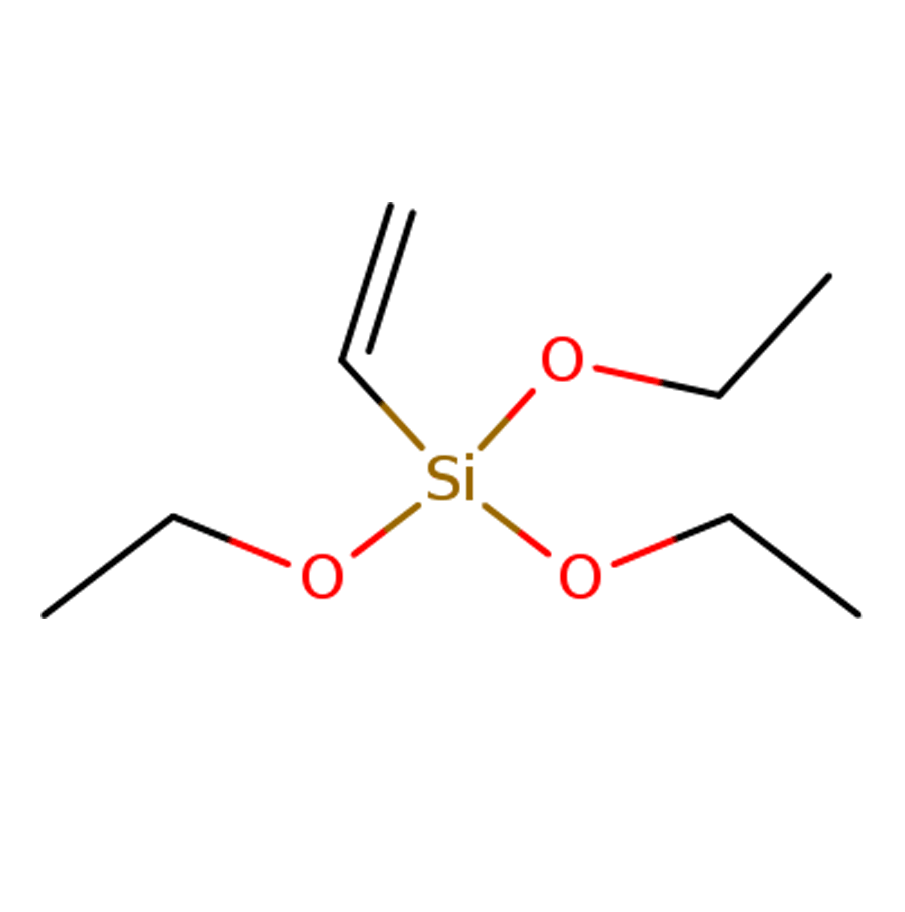

Vinyl silanes are organosilicon compounds featuring a vinyl functional group and a reactive alkoxy group. This unique structure enables vinyl silanes to function as effective crosslinkers, forming strong Si-O-Si linkages. The vinyl group facilitates crosslinking with organic polymers, while various alkoxy groups allow vinyl silanes to bond with inorganic materials, enhancing adhesion and wettability. These properties make vinyl silanes ideal for improving the performance and durability of coatings, adhesives, and composites.

| CAS NO. | Product Name |

| 2768-02-7 | Vinyltrimethoxysilane |

| 78-08-0 | Vinyltriethoxysilane |

| 1067-53-4 | Vinyltris(2-methoxyethoxy) silane |

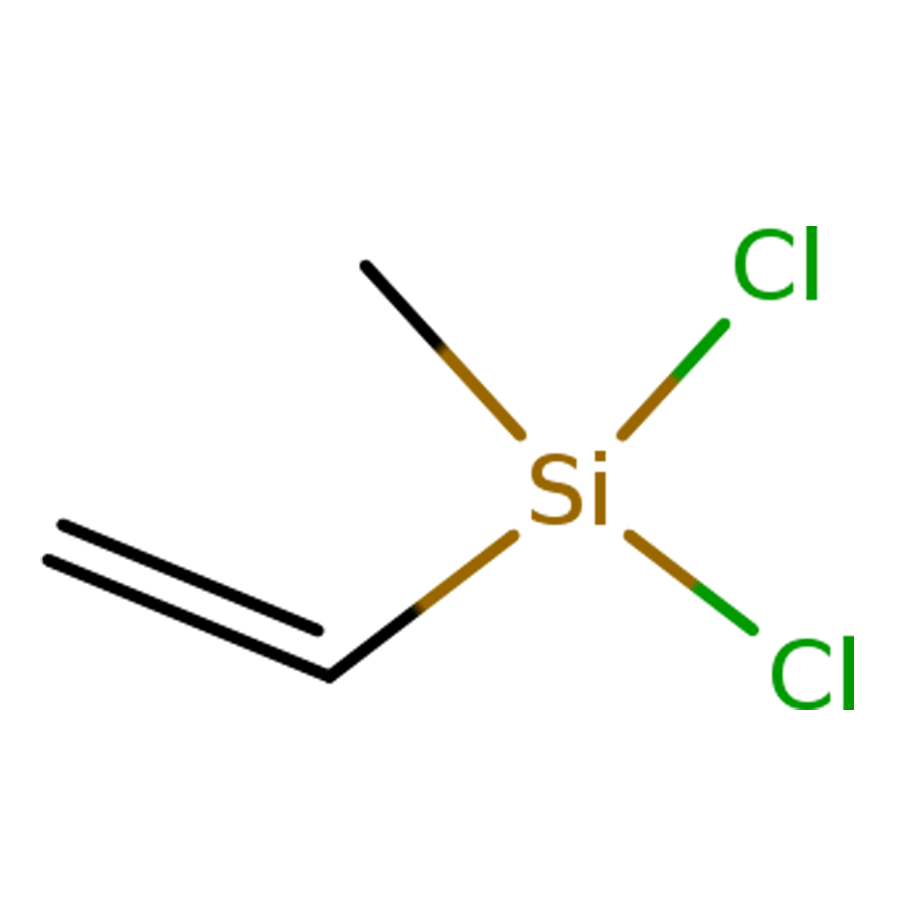

| 124-70-9 | Methylvinyldichlorosilane |

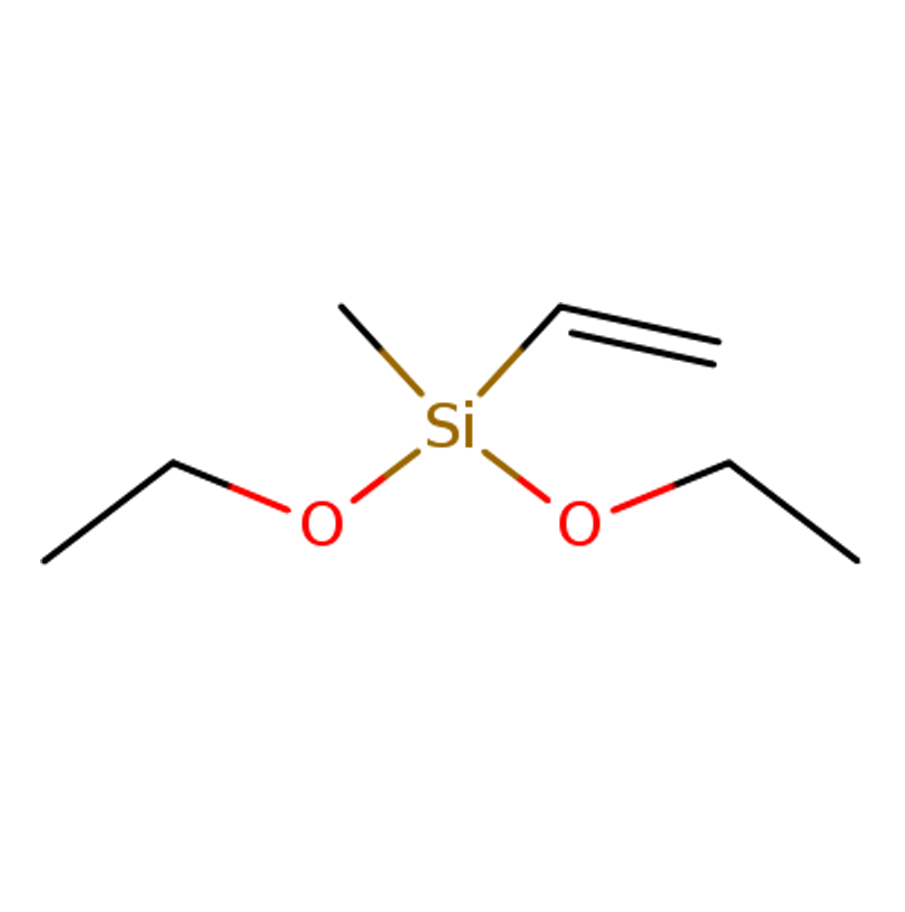

| 16753-62-1 | Methylvinyldimethoxysilane |

| 5507-44-8 | Methylvinyldiethoxysilane |

Functions & Applications of Vinyl Silanes

In addition to crosslinked polyethylene applications, Silico vinyl silanes are widely used in sealants and coatings. As adhesion promoters, they significantly enhance bonding to various inorganic substrates. Vinyl silanes with reactive methoxy groups are ideal moisture scavengers for MS polymer processing, making them suitable for moisture-sensitive systems.

Silico offers a range of vinyl silanes, including methylvinyldimethoxysilane, for applications like electronic encapsulation. For more information, please contact Silico’s customer service team.

Main Markets of Vinyl Silanes

Silico vinyl silanes are widely utilized across various industries, with the largest consumption in the wires, cables, and pipes sector. Vinyl silanes can be grafted onto unsaturated polymers such as polyethylene and polyester, enhancing the crosslinking process in XLPE cables and PEX-b pipes.

In these applications, Silico’s vinyl silanes, including Vinyltrimethoxysilane and Vinyltriethoxysilane, serve as silane grafting agents and crosslinking agents. Once grafted, the resins can be crosslinked under moisture cure conditions.

These vinyl silanes improve mechanical and electrical properties, including high-temperature resistance, weatherability, tensile strength, and tear strength. They also increase the oxygen index and enhance the durability of organic resins. For Low Smoke Halogen-Free Flame Retardant wires and cables, Silico’s Vinyltris(2-methoxyethoxy)silane is often selected to improve the dispersion of flame-retardant powders or fillers.

Packaging Specifications

Silico® Prouducts

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

How to Select Vinyl Silanes?

Vinyl silanes are compounds that contain a vinyl group and a reactive alkoxy group, making them effective crosslinkers and adhesion promoters for both organic polymers and inorganic materials.

Key Factors to Consider:

Compatibility with Functional Groups: Ensure the vinyl group matches the reactivity needs of your target material, such as polyethylene or polyester.

Alkoxy Group Type: Choose the appropriate alkoxy group to ensure reactivity with the substrate. For example, monoalkoxy silanes are ideal for dry fillers, while others work better with wet fillers.

Application Needs: Select vinyl silanes based on desired properties like improved strength, electrical conductivity, or adhesion.

By considering these factors, you can choose the right vinyl silane for your specific application.