Silico® V401 Vinyl Silicone Oil (Linear Type)

Silico® -V401 (CAS 68083-19-2) is a linear poly(dimethylsiloxane) with vinyl groups at both ends. It offers high reactivity with hydrogen-containing silicone oils (catalyst-assisted), no pendent chains like branched types, and better compatibility with organic materials than methyl silicone oils. It also has other excellent properties.

Product Features

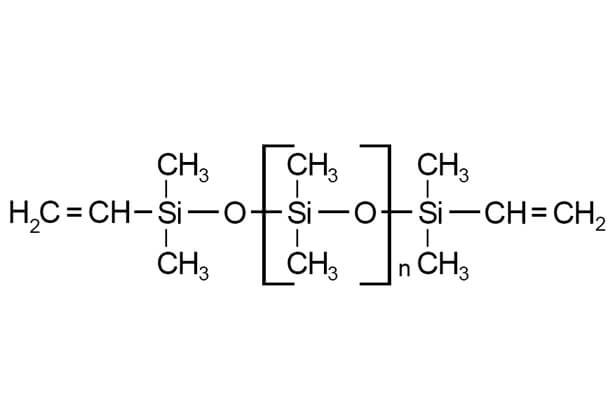

Silico® -V401 (CAS 68083-19-2) is a linear poly(dimethylsiloxane) with vinyl groups at both ends of the molecular chain. Its molecular structure is as follows:

(CH₂=CH)(CH₃)₂SiO[(CH₃)₂SiO]ₙSi(CH₃)₂(CH=CH₂)

The vinyl content decreases as the molecular weight increases. This product is an active intermediate material with several key advantages:

The vinyl groups at both ends have high reactivity, allowing fast addition reactions with hydrogen-containing silicone oils (catalyst-assisted) and other reactions.

Unlike branched vinyl silicone oils, it has no pendent chains, offering a more streamlined molecular structure.

It offers superior compatibility with organic materials compared to methyl silicone oils, enhancing blending potential with other organic compounds.

Other exceptional properties.

Technical Specifications

| Product Model | Viscosity (25°C, cp) | Vinyl Content (mol/100g) |

|---|---|---|

| V401-40 | 10-50 | 0.06-0.08 |

| V401-90 | 90±5 | 0.020-0.047 |

| V401-180 | 180±10 | 0.022-0.034 |

| V401-310 | 100-500 | 0.013-0.02 |

| V401-500 | 500±25 | 0.013-0.027 |

| V401-1000 | 1000±50 | 0.0067-0.014 |

| V401-2000 | 2000±100 | 0.0067-0.0135 |

| V401-2500 | 2500±125 | 0.0067-0.014 |

| V401-5000 | 5000±250 | 0.0040-0.0081 |

| V401-10000 | 10000±500 | 0.0027-0.0054 |

Applications

Used as a filler in silicone rubber production to enhance strength and hardness.

Key material for producing liquid silicone rubber, particularly for injection molding and hot-pressing.

Reacts with various organic materials, including polyurethane and acrylics, to create superior materials with enhanced weather resistance, aging resistance, UV protection, and improved toughness (e.g., coatings).

Other potential and developing applications.

Usage and Dosage

For filling or modification: 5%-10% addition.

For base rubber: 50%-100% addition.

Precautions

This product is chemically active. During storage and transportation, avoid contamination (especially with catalysts). When using or blending with other materials, ensure that no chemical reactions are triggered to prevent degradation.

Packaging & Storage

Packaging: Available in 50kg, 200kg, and 1000kg plastic drum packaging.

Storage: Store in a sealed container at room temperature. Avoid contact with strong acids and alkalis. The shelf life in unopened packaging is 12 months from the production date.

Transportation: Handle as a non-toxic, non-hazardous material.

All technical data provided is based on current knowledge and experience. Users must test product suitability for intended applications.

No warranties are expressed or implied. Silico® assumes no liability for incidental or consequential damages.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.