Silico® Mercapto Functional Silicone Fluids

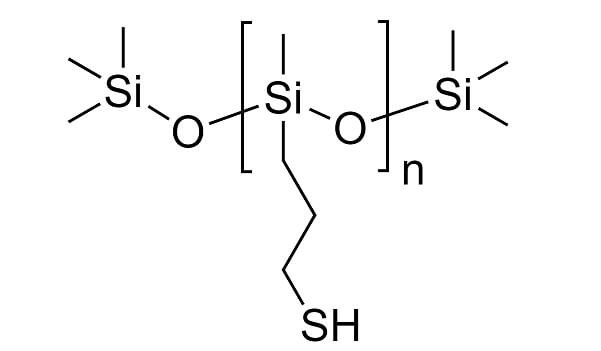

Mercapto-functional silicone fluids (–SH terminated or pendant) are specialty reactive silicones featuring thiol groups that enable chemical bonding with various substrates. These fluids offer excellent surface reactivity, thermal stability, and compatibility in a wide range of industrial applications, including release agents, UV-curable coatings, and surface modification technologies.

Applications of Mercapto Silicone Fluids

Mercapto-functional silicones are widely used in the following applications due to their high surface activity and reactivity:

Release agents for rubber, plastic, and metal molding

Enhance demolding performance under extreme temperatures and pressures.Corrosion-resistant coatings for metals

Thiol groups chemically bond to metallic surfaces, improving durability and barrier properties.UV/EB curable coatings and adhesives

React via free radical chemistry to enhance adhesion and crosslink density.Organic–inorganic hybrid synthesis

Serve as intermediates for grafting thiol groups onto polysiloxanes or organic polymers.Textile and fiber treatment

Improve softness, antistatic behavior, and surface energy of synthetic and natural fibers.

Recommended Mercapto Functional Silicone Fluids

Packaging Specifications

Why Choose Silico® Organsilicon?

Silico® Prouducts

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

How to Choose Mercapto Functional Silicone Fluids ?

When selecting mercapto silicone fluids, consider the following key factors to optimize performance for your formulation or process:

Viscosity: Influences coating uniformity and processability. Low-viscosity grades are suited for surface treatment and coatings, while high-viscosity options benefit structural applications.

Thiol Content (–SH%): Determines reactivity. Higher SH% offers faster curing and stronger bonding.

Molecular Weight: Affects mechanical strength, film-forming ability, and thermal stability.

Solubility & Compatibility: Ensure compatibility with solvents, polymers, or substrate materials in your formulation.