lsocyanate Silanes

lsocyanate Silanes

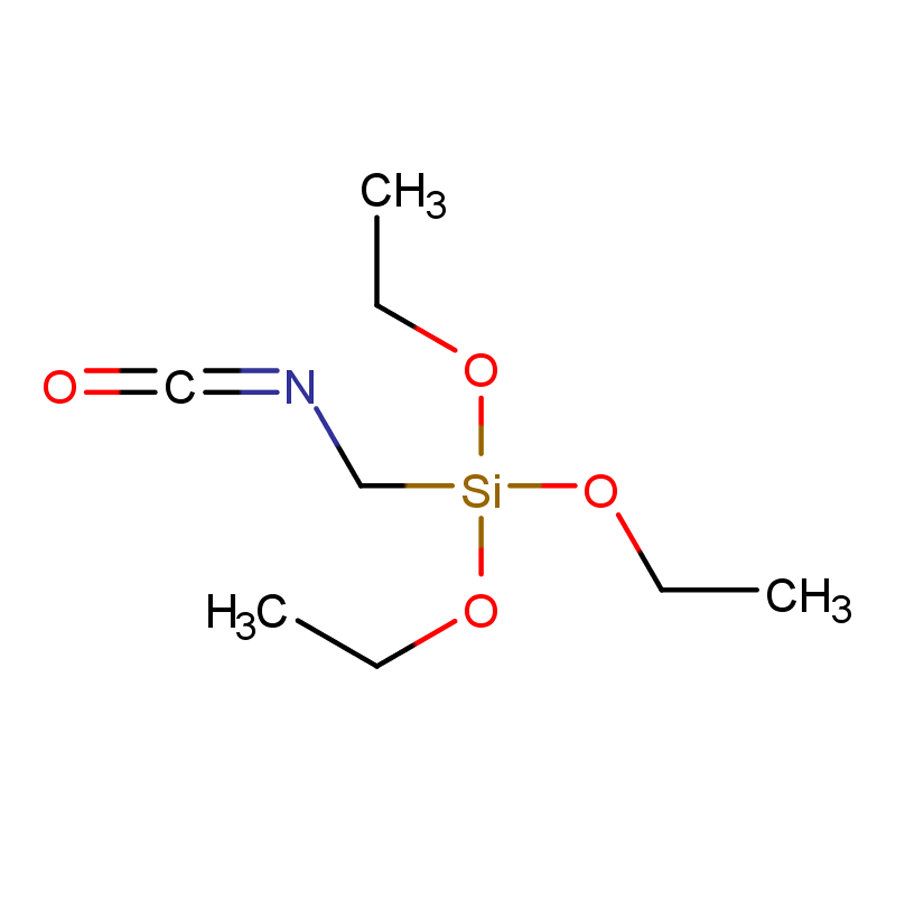

Isocyanate silanes are hybrid compounds that integrate an isocyanate (-N=C=O) functional group with hydrolyzable alkoxy groups. These silanes exhibit the characteristic reactivity of alkyl isocyanates, enabling them to efficiently bond with active hydrogen-containing organic polymers. Upon hydrolysis, the alkoxy groups convert into highly reactive silanol groups, enhancing adhesion to a wide range of inorganic substrates such as glass, metals, and minerals. With their dual reactivity, Silico isocyanate silanes serve as excellent coupling agents, improving durability, moisture resistance, and interfacial bonding in coatings, adhesives, and composite materials.

| CAS NO. | Product Name |

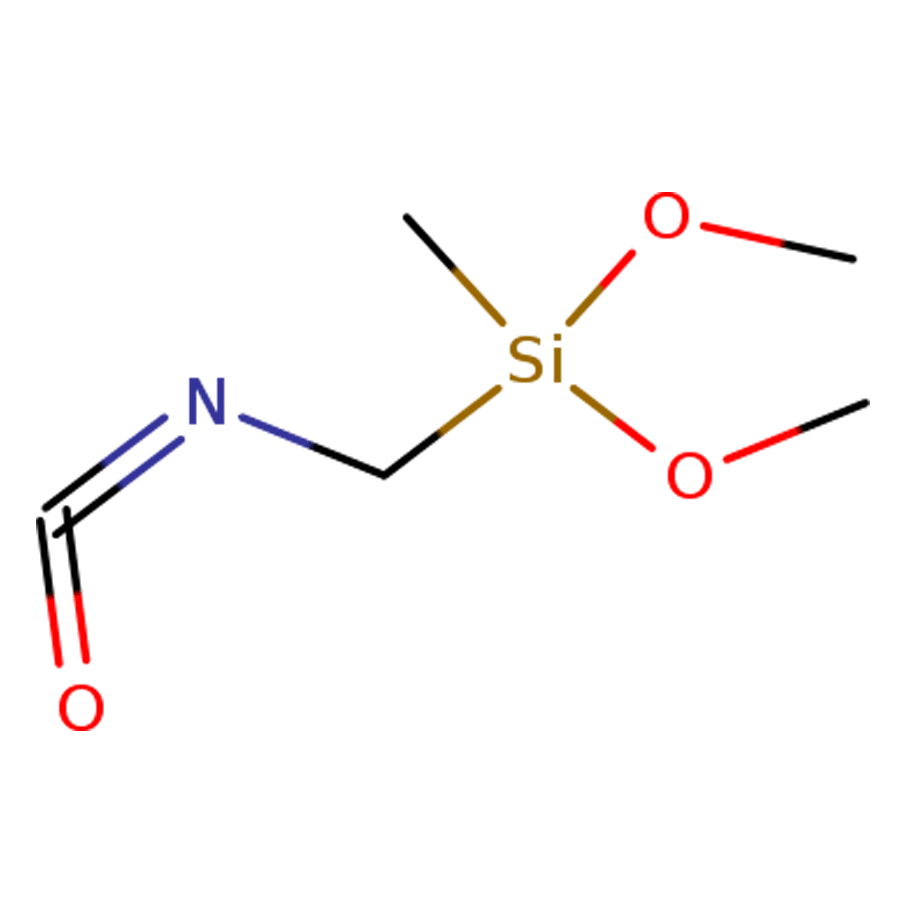

| 406679-89-8 | (Isocyanatomethyl) methyldimethoxysilane |

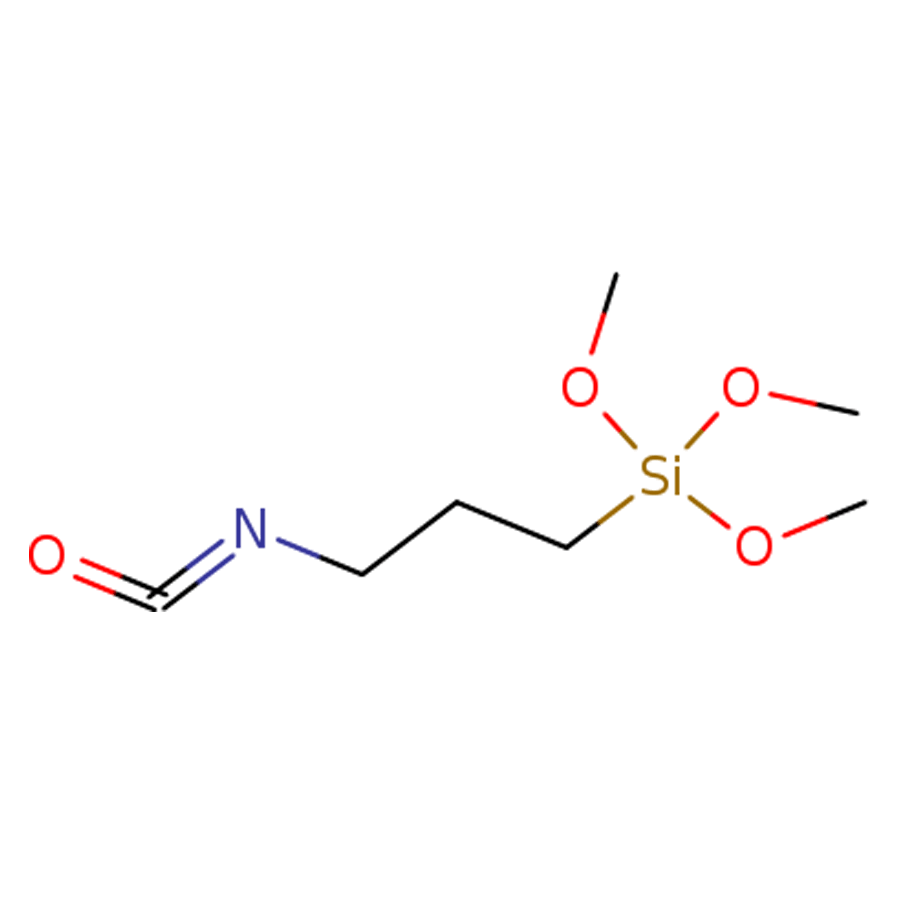

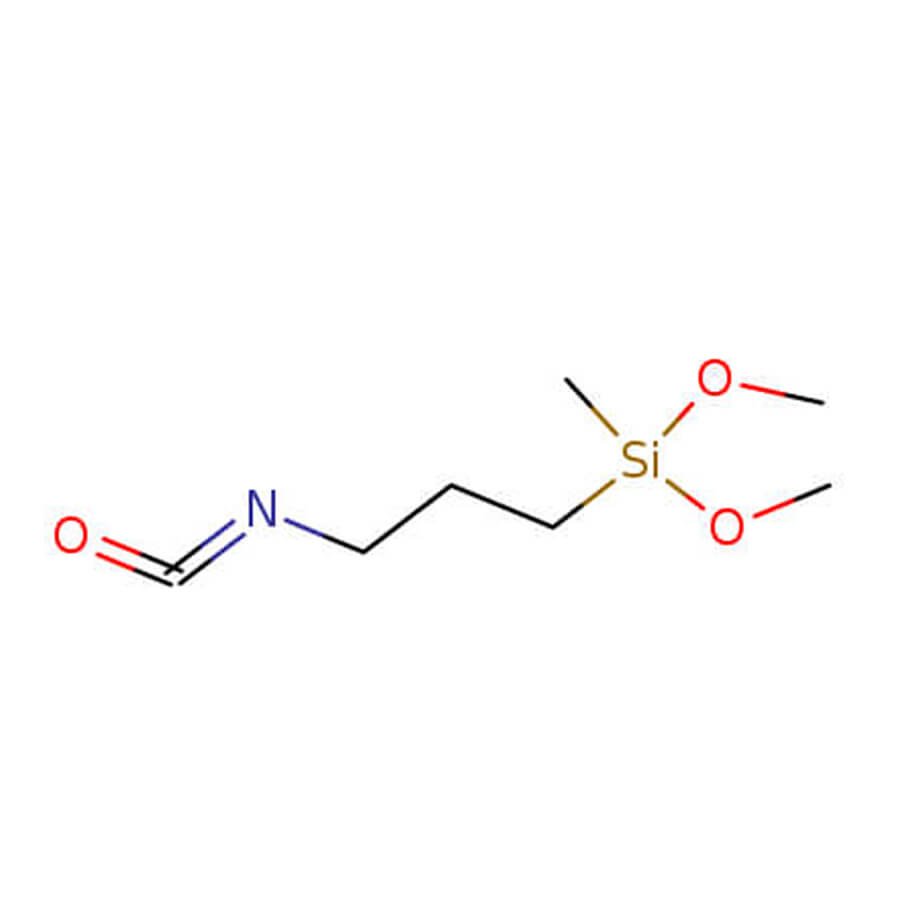

| 15396-00-6 | 3-Isocyanatopropyltrimethoxysilane |

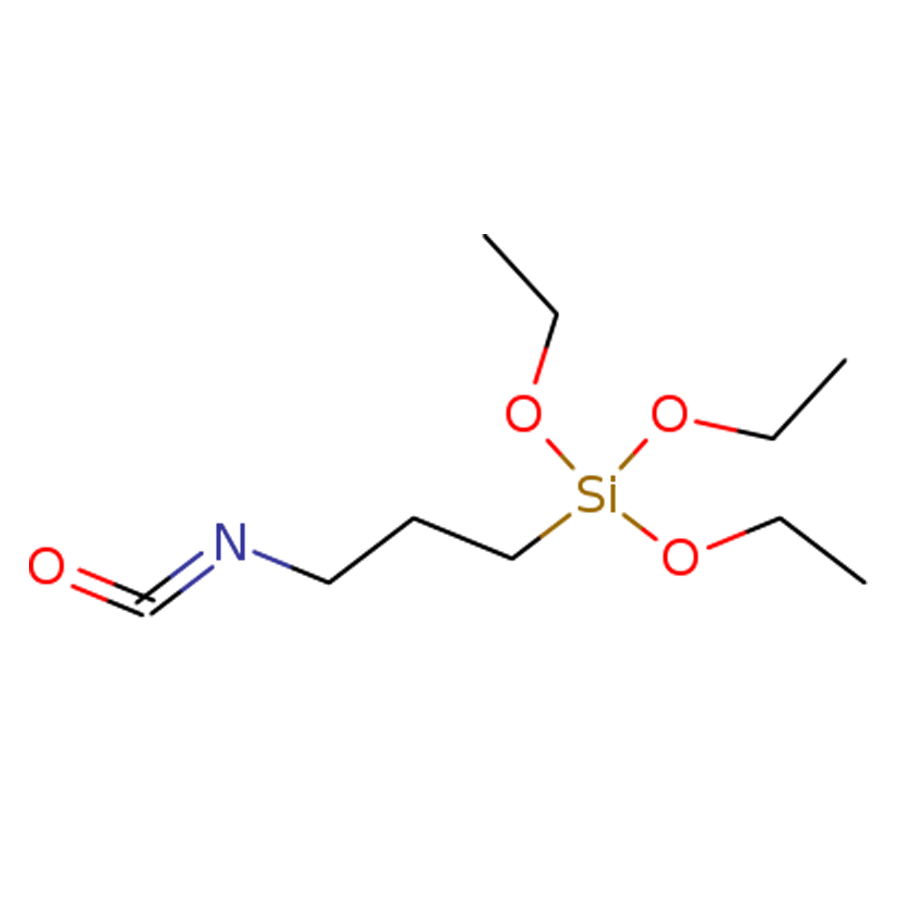

| 24801-88-5 | 3-Isocyanatopropyltriethoxysilane |

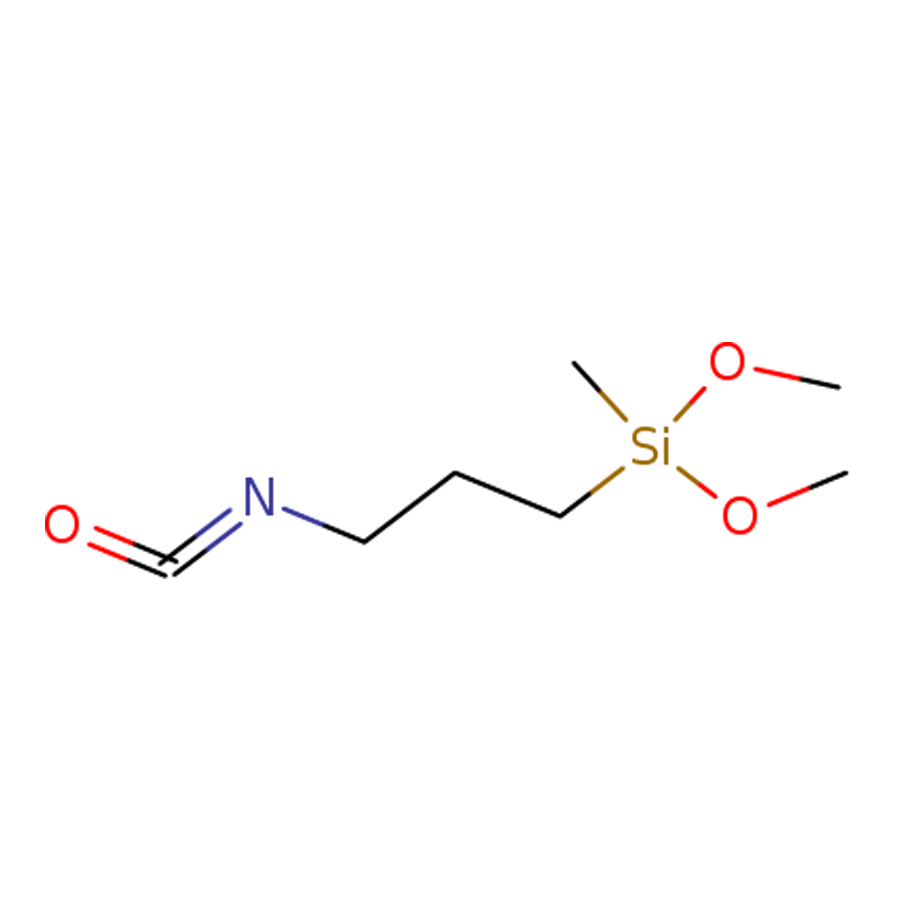

| 26115-72-0 | (3-Isocyanatopropyl)methyl dimethoxysilane |

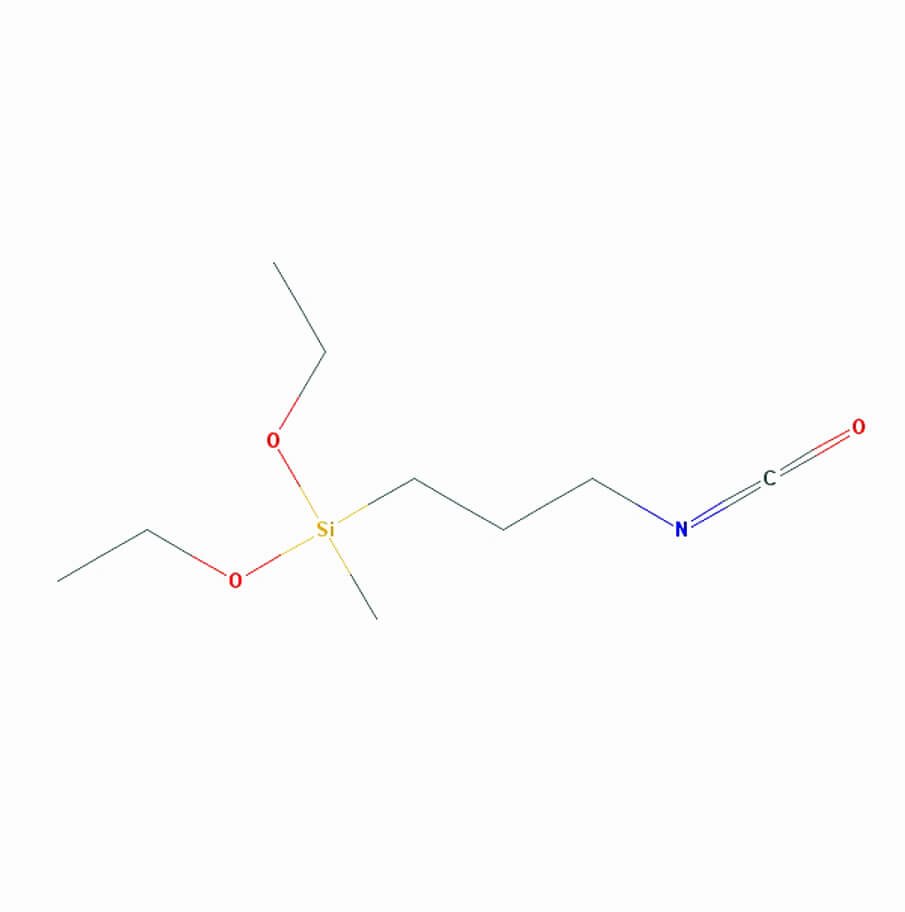

| 33491-28-0 | 3-Isocyanatopropylmethyl diethoxysilane |

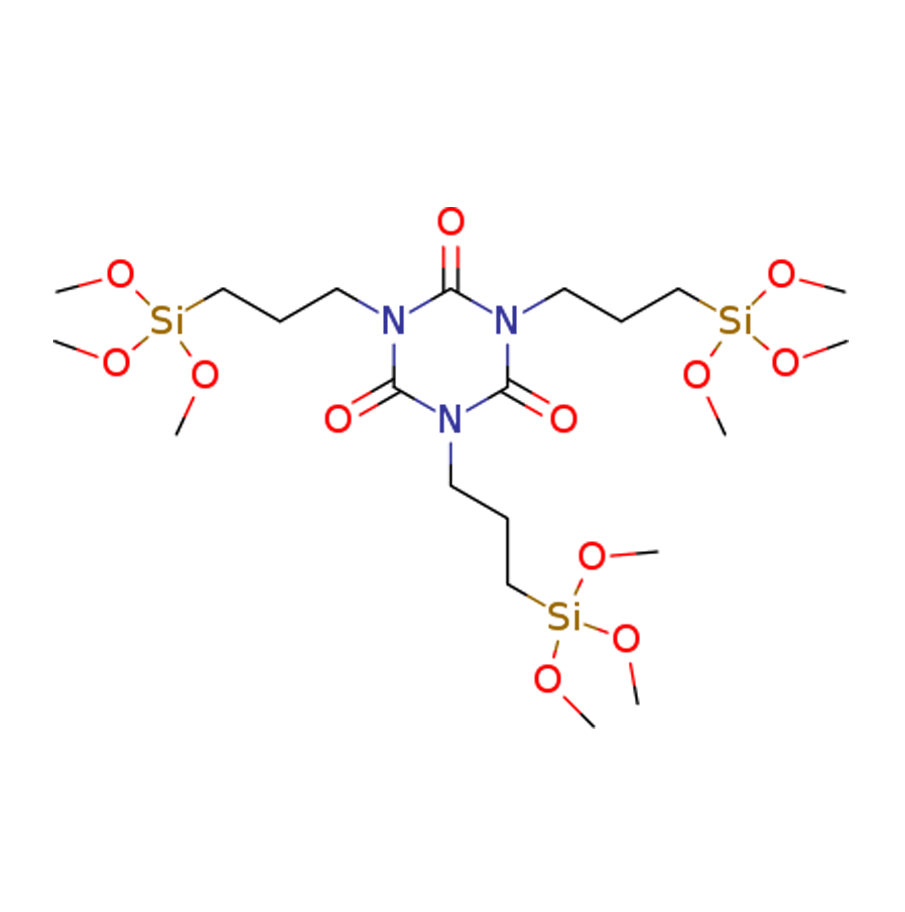

| 26115-70-8 | Tris[3-(Trimethoxysilyl)propyl] Isocyanurate |

| 82194-46-5 | Tris[3-(Triethoxysilyl)propyl] Isocyanurate |

| 78450-75-6 | Isocyanatomethyltrimethoxysilane |

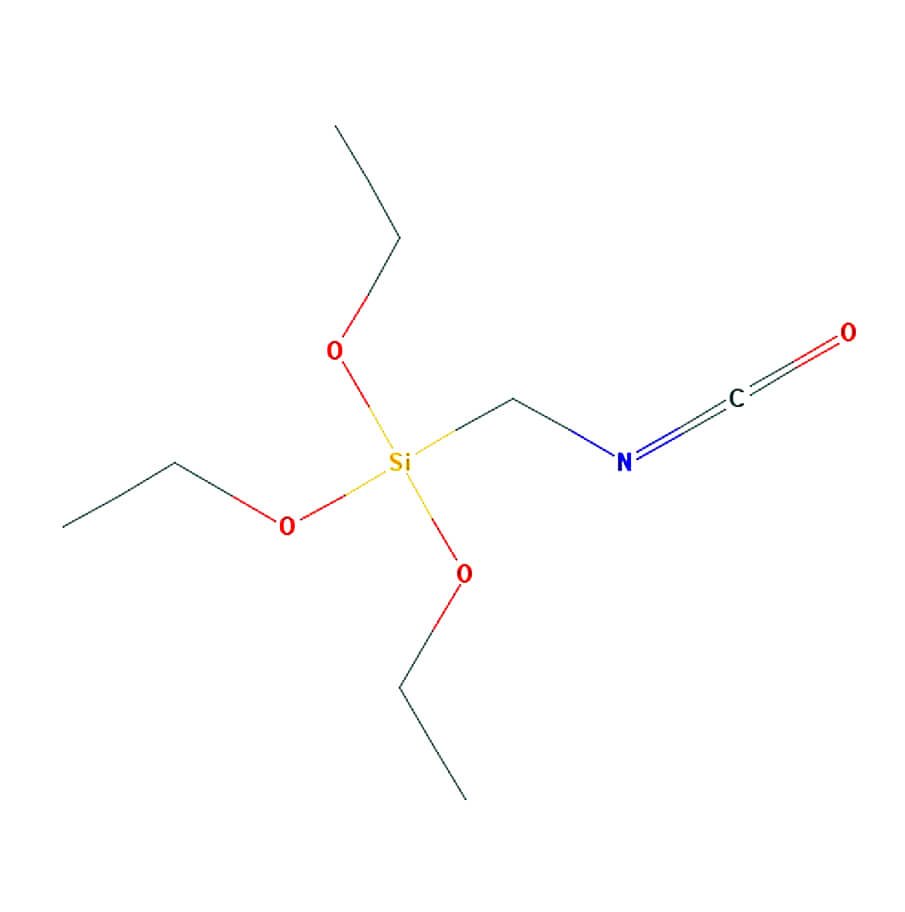

| 132112-76-6 | Triethoxy(isocyanatomethyl)silane |

Functions & Applications of Isocyanate Silanes

Silico isocyanate silanes serve as highly effective adhesion promoters in paints, coatings, adhesives, and sealants, enhancing adhesion to organic substrates while improving hydrophobic properties.

These silanes play a crucial role in one-component moisture-curable polyurethanes and two-component reactive urethane coatings. Additionally, they function as crosslinkers in urethane sealants and coatings, significantly enhancing mechanical strength and durability.

A major application of Silico isocyanate silanes is in silyl-modified polyurethane (SPUR) polymers, where they act as essential crosslinking agents. Beyond SPUR polymers, they are also used in silane-modified polymers (SMP) or MS polymers, both widely utilized in sealant formulations for construction and industrial applications. The incorporation of isocyanate silanes improves polymer modification, strengthening mechanical and chemical properties in advanced composite materials.

Production Status of Isocyanate Silanes/NCO Silanes

Silico is a leading manufacturer of isocyanate silanes in China, with a production capacity of approximately 80 metric tons per month. The company offers high-purity isocyanate silanes (≥98%) that meet industrial standards. These silanes are widely utilized as adhesion promoters, crosslinkers, and surface modifiers in coatings, adhesives, and sealants.

While the most commonly used isocyanate silanes are produced regularly, other specialized variants are available on a made-to-order basis or manufactured in pilot-scale facilities due to lower market demand. Silico remains committed to advancing the development of high-performance isocyanate silanes to meet evolving industry needs.

Packaging Specifications

Silico® Prouducts

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

How to Select Isocyanate silanes?

When selecting an isocyanate silane, consider these key factors:

- Functional Compatibility – Ensure it reacts well with your materials, such as resins with hydroxyl, carboxyl, or amino groups.

- Application Needs – Choose based on its role, whether as an adhesion promoter, surface modifier, or resin modifier.

- Substrate Type – Different silanes suit different surfaces, like methoxy-functional silanes for glass or amino-functional silanes for metals.

- Processing Conditions – Factors like temperature, humidity, and curing affect performance.

Selecting the right isocyanate silane enhances adhesion, durability, and overall efficiency.