Chloro Silanes

Chloro Silanes

Chloro silanes are reactive silicon compounds containing at least one silicon-chlorine bond. They serve as fundamental intermediates in silicone production, leading to products like sealants, adhesives, lubricants, and coatings. In water, chloro silanes hydrolyze, releasing hydrogen chloride and forming silanol groups, which can further react to create siloxane linkages. Specific types, such as dimethylchlorosilane and trichlorosilane, are utilized in synthesizing silicone polymers and producing ultrapure silicon for the semiconductor industry.

| CAS NO. | Product Name |

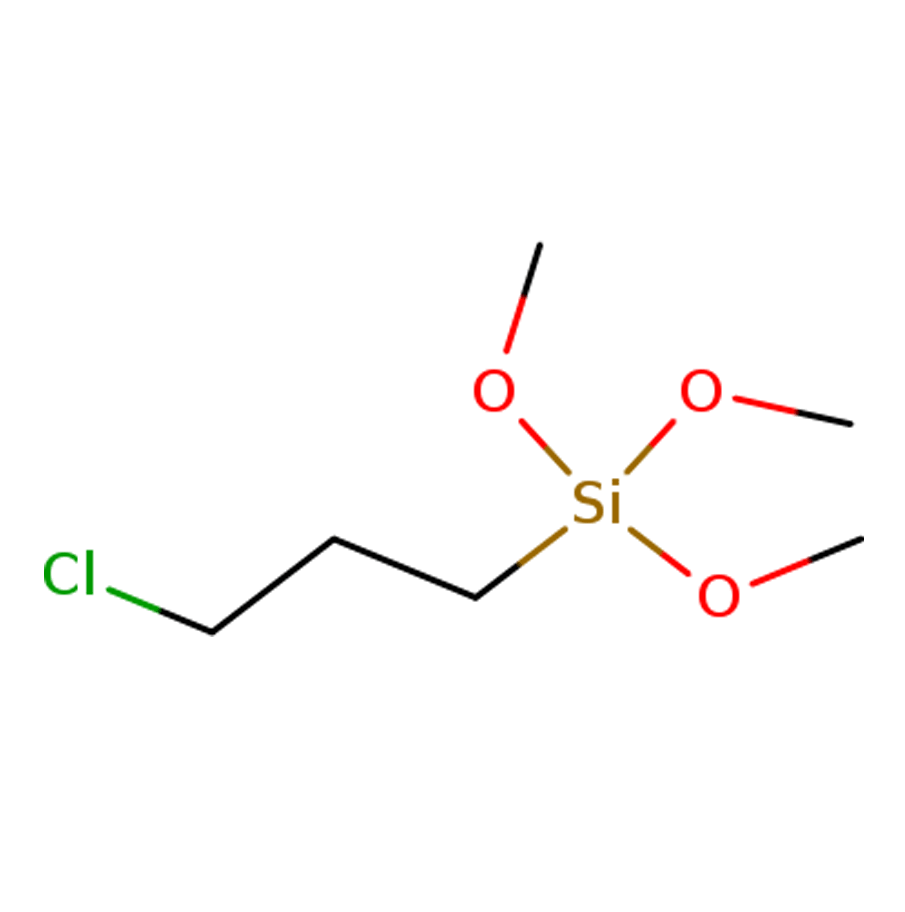

| 2530-87-2 | 3-Chloropropyltrimethoxysilane |

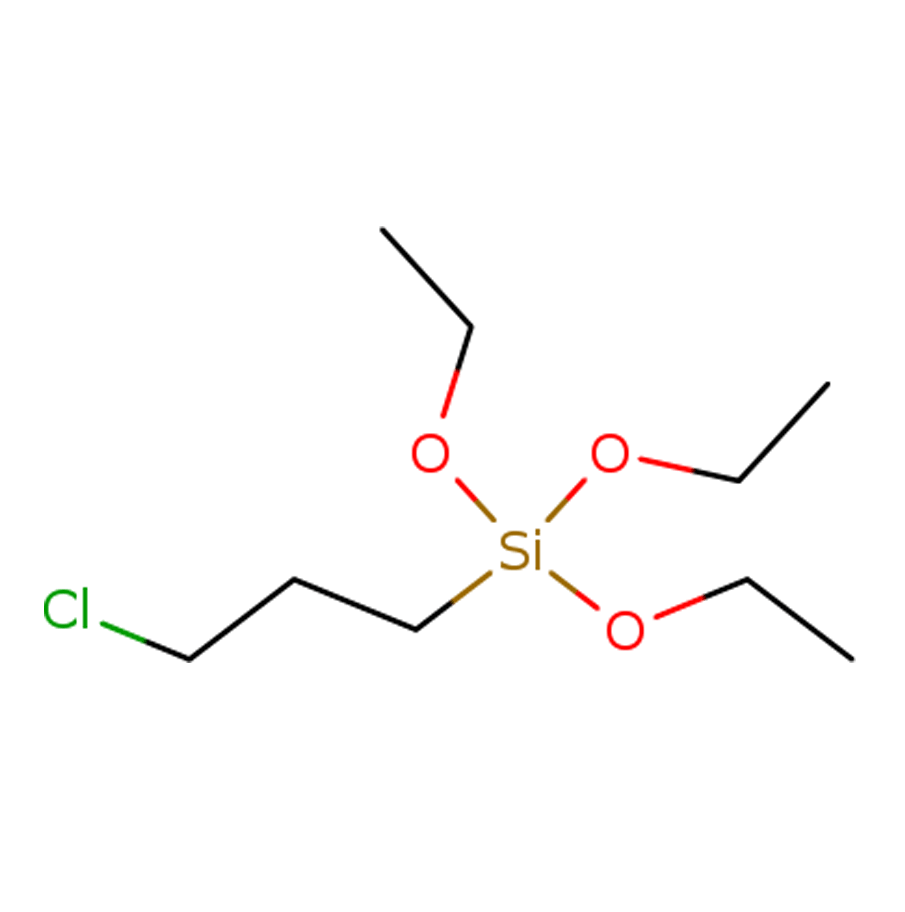

| 5089-70-3 | 3-Chloropropyltriethoxysilane |

| 13501-76-3 | 3-Chloropropyl methyldiethoxysilane |

| 18171-19-2 | 3-Chloropropyl methyldimethoxysilane |

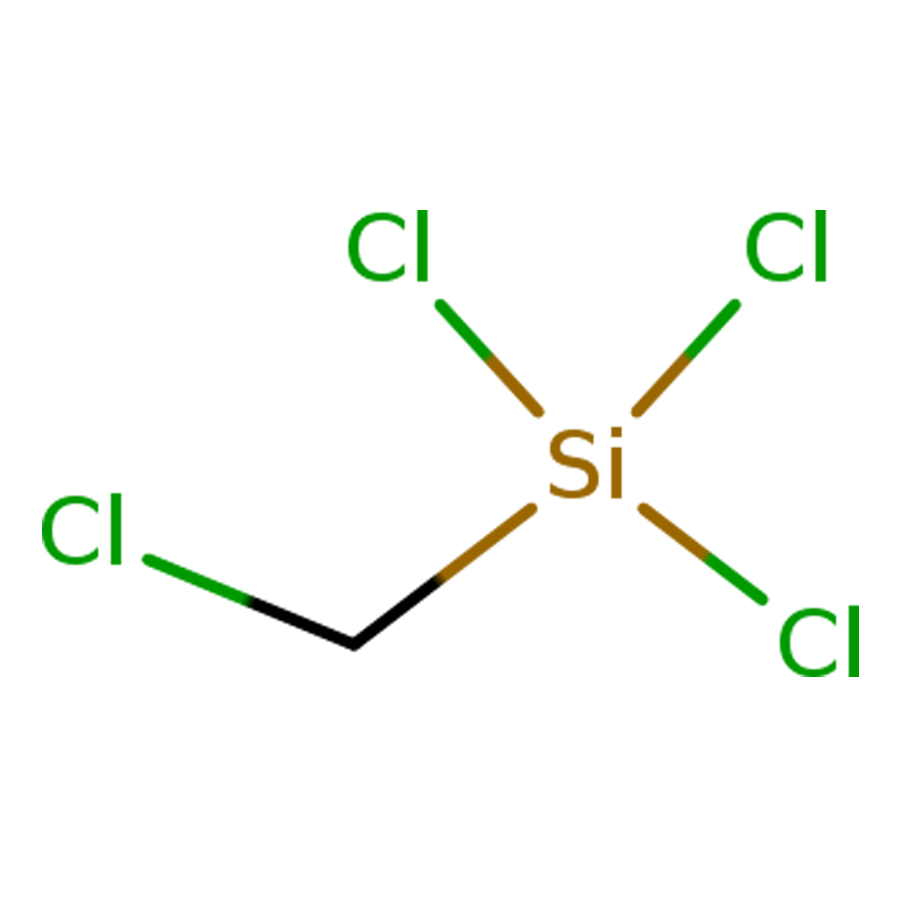

| 1558-25-4 | 3-Chloromethyltrichlorosilane |

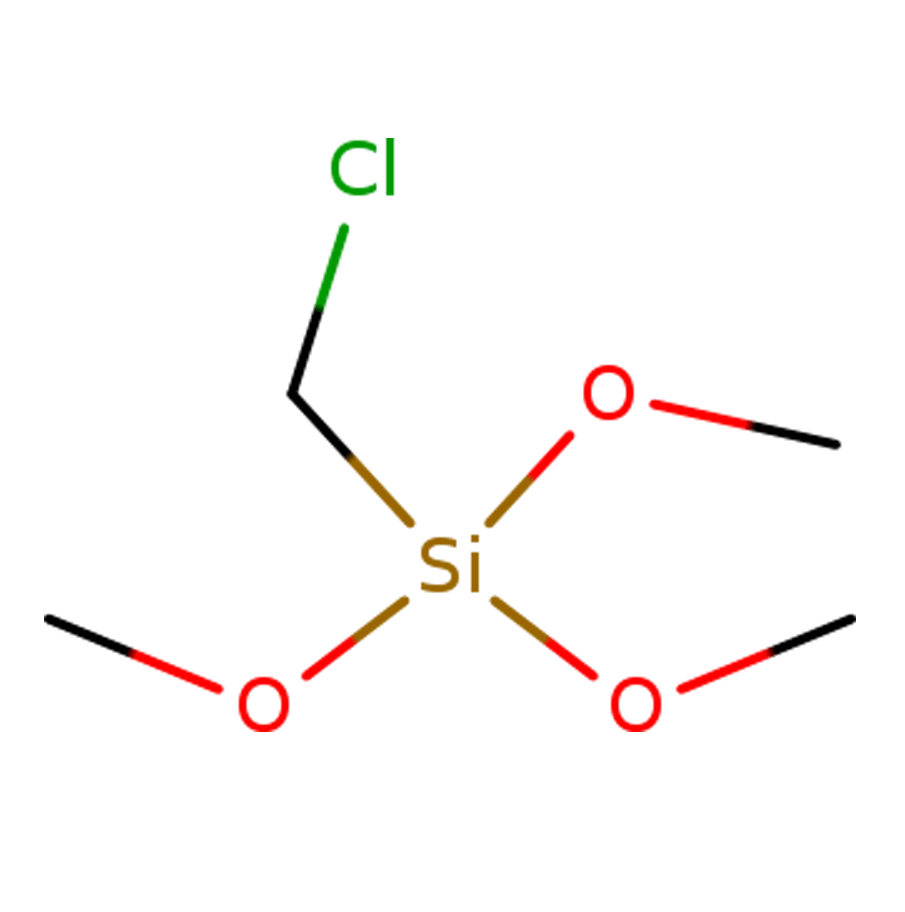

| 5926-26-1 | Chloromethyltrimethoxysilane |

| 15267-95-5 | Chloromethyltriethoxysilane |

| 13508-53-7 | Chloromethylethoxydimethylsilane |

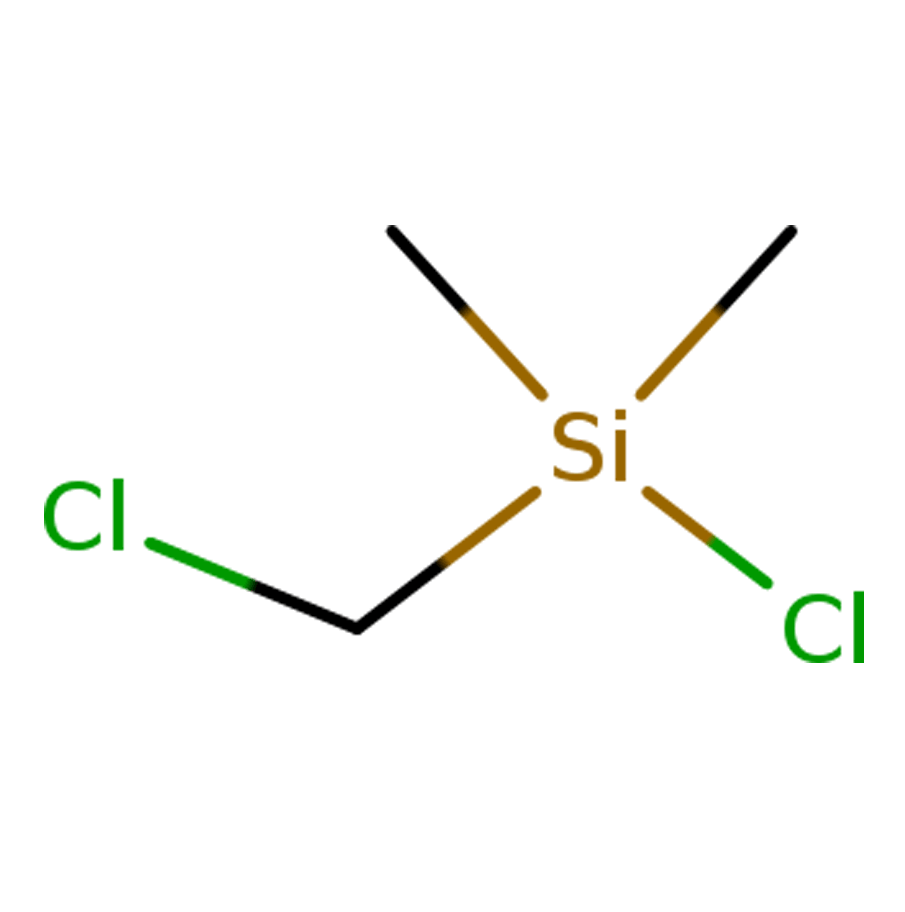

| 1719-57-9 | Chloromethyldimethylchlorosilane |

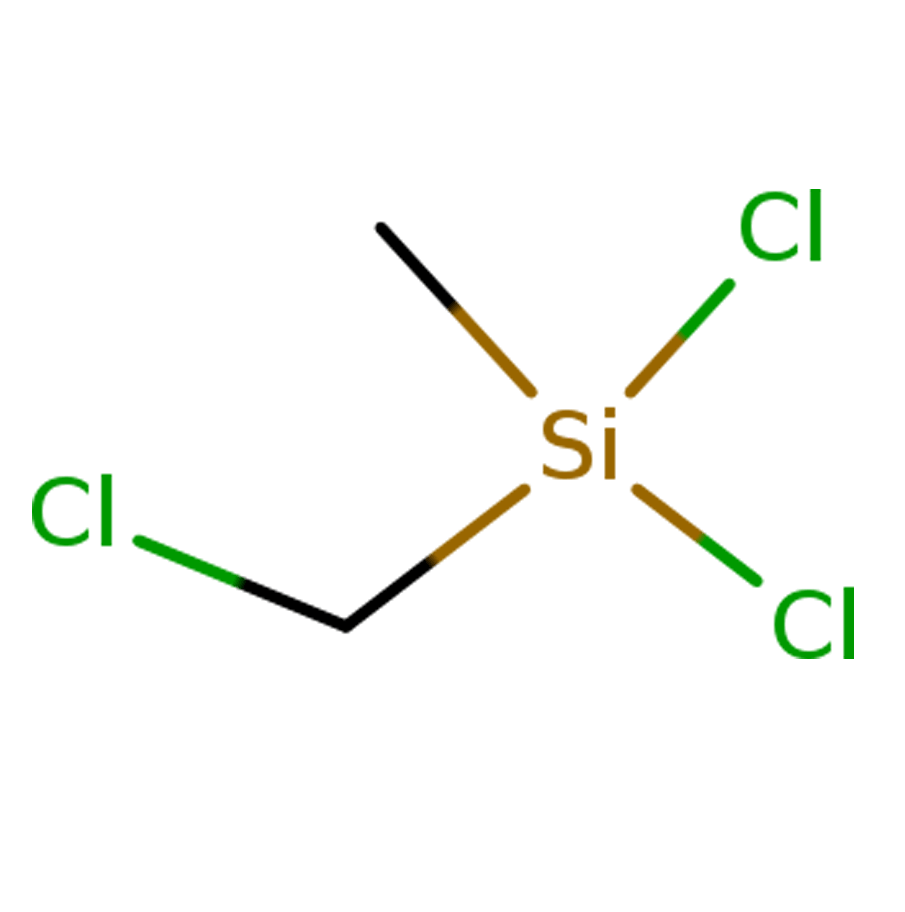

| 1558-33-4 | Chloromethylmethyldichlorosilane |

Key Features of Chloro Silanes

Chlorosilanes are reactive chemical compounds characterized by at least one silicon-chlorine (Si-Cl) bond. They are typically colorless or light-yellow liquids with pungent odors and are insoluble in water. A notable feature of chlorosilanes is their high reactivity with moisture, leading to the release of hydrogen chloride gas. This moisture sensitivity necessitates careful handling and storage to prevent hazardous reactions. Chlorosilanes serve as essential intermediates in the production of silicones, where their reactivity is harnessed to synthesize various silicone-based materials.

Functions & Applications of Chloro Silanes

Chloro silanes are highly reactive organosilanes used as key intermediates in silicone synthesis, surface modification, and material processing. Their chlorine and alkoxy groups enable strong bonding, hydrolysis, and functionalization.

Functions:

- Silicone Synthesis: Essential for producing silicones, resins, and siloxanes.

- Surface Treatment: Enhances adhesion, hydrophobicity, and compatibility.

- Crosslinking & Coupling: Strengthens polymer networks and improves durability.

Applications:

- Silicone Polymers: Used in sealants, elastomers, and lubricants.

- Coatings & Adhesives: Improves adhesion to glass, metal, and ceramics.

- Semiconductors & Electronics: Acts as a precursor in microelectronics.

- Chemical Processing: Functions as a key intermediate in advanced materials.

Chloro silanes play a crucial role in high-performance materials, ensuring enhanced stability and reactivity.

Packaging Specifications

Silico® Prouducts

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

How to Select a Chloro Silanes?

Selecting the right chloro silane depends on key factors:

- Functional Groups – Different chloro silanes have varying reactivity. For example, 3-Chloropropyltrimethoxysilane improves adhesion in coatings and composites.

- Application Needs – Trichlorosilane is essential for semiconductor-grade silicon production.

- Reactivity & Safety – Chloro silanes react with moisture, releasing hydrogen chloride, requiring careful handling.

- Purity – High-purity options are crucial for electronics and advanced materials.

Choosing the right type ensures efficiency, safety, and the best performance in your application.