How to Choose the Right PDMS Material for Your Application

- Blog

- June 18, 2022

- 4:07 pm

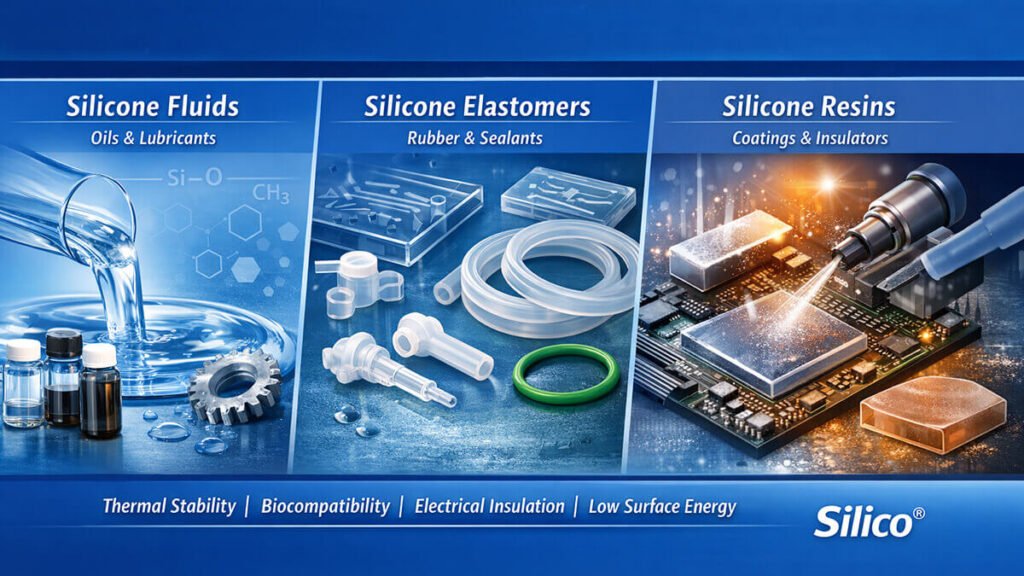

Polydimethylsiloxane (PDMS) is a widely used organosilicon polymer characterized by a silicon–oxygen (Si–O) backbone with methyl side groups. PDMS materials span an exceptionally broad product spectrum—from low-viscosity silicone fluids used in lubrication and mold release to highly crosslinked elastomers applied in sealing, damping, and microfluidic devices.

Key advantages of PDMS include:

- Wide service temperature range

- Excellent thermal and oxidative stability

- Low surface energy and hydrophobicity

- Superior electrical insulation

Proven biocompatibility in many formulations

Because of these attributes, PDMS plays a critical role in industries such as microfluidics, biomedical engineering, electronics, lubrication, coatings, and specialty chemicals. High-purity PDMS materials, such as those developed by Silico®, are increasingly adopted in applications requiring performance consistency and regulatory compliance.

Table of Contents

- 1. Chemical Structure and Manufacturing Routes of PDMS (Overview)

- 2. The PDMS Family: Elastomers, Fluids, and Resins

- 3. Key Physical and Chemical Properties (Engineering Perspective)

- 4. Common Processing and Curing Systems

- 5. Typical Products and Grades

- 6. Major Application Areas

- 7. Selection Guide: How to Choose the Right PDMS

- 8. Processing Considerations and Common Issues

- 9. Environment, Health, and Regulatory Compliance

- 10. Conclusion and Recommended Reading

1. Chemical Structure and Manufacturing Routes of PDMS (Overview)

The fundamental repeating unit of PDMS is:

–[Si(CH₃)₂–O]–

Industrial production commonly starts from dichlorodimethylsilane via hydrolysis and condensation, or from cyclic siloxanes (e.g., D4) through anionic ring-opening polymerization. Molecular weight, chain architecture, and functionality are precisely controlled by:

- End-group modification

- Introduction of functional substituents (vinyl, amino, phenyl)

- Incorporation of tri- or tetra-functional monomers

By adjusting these parameters, manufacturers can produce linear silicone fluids, lightly crosslinked elastomers, or highly crosslinked silicone resins. Both academic and industrial literature provide extensive discussions on catalysts, polymerization conditions, and molecular control strategies.

2. The PDMS Family: Elastomers, Fluids, and Resins

Silicone fluids are linear or lightly branched PDMS polymers with viscosities typically expressed in centistokes (cSt at 25°C), ranging from <10 cSt to >1,000,000 cSt. Typical applications include:

- Lubrication and damping

- Mold release agents

- Antifoaming agents

- Cosmetic and personal care formulations

- Heat resistance

- UV and weathering stability

- Electrical insulation

These materials are commonly used in high-temperature coatings, protective finishes, and electrical insulation systems.

3. Key Physical and Chemical Properties (Engineering Perspective)

Thermal Stability

PDMS maintains performance over a broad temperature range (typically –50°C to +200°C, with short-term tolerance above this), making it suitable for automotive, electronics, and industrial processes.

Mechanical and Viscoelastic Behavior

Crosslink density governs modulus and elastic recovery. Uncrosslinked PDMS behaves as a viscous fluid, while elastomers exhibit pronounced viscoelasticity and time-dependent deformation.

Electrical Properties

PDMS offers high dielectric strength and low dielectric loss, supporting its use in electronic encapsulation and insulation.

Surface Properties and Compatibility

PDMS is inherently hydrophobic with low surface energy. Oxygen plasma treatment can temporarily render the surface hydrophilic, but hydrophobic recovery typically occurs over time. PDMS swells significantly in many nonpolar organic solvents but shows minimal swelling in water and polar alcohols.

4. Common Processing and Curing Systems

Addition Cure (Platinum-Catalyzed)

- No by-products

- Excellent dimensional stability

- Common in LSR and medical-grade silicones

- Sensitive to sulfur, amines, and certain inhibitors

Condensation Cure (RTV)

- Room-temperature or heat-assisted curing

- Generates small-molecule by-products (e.g., alcohols, acetic acid)

- Suitable for on-site sealing and general-purpose adhesives

Peroxide Cure

- Traditional high-temperature vulcanization method

- Robust and cost-effective for industrial production

May generate extractables or cause discoloration

5. Typical Products and Grades

Silicone Fluids by Viscosity

From ultra-low viscosity fluids (<10 cSt) to ultra-high viscosity gums (>1,000,000 cSt). Selection should consider temperature dependence, volatility, and surface behavior.

Elastomer Categories

- RTV: casting, sealing, prototyping

- LSR: high-volume injection molding, precision parts

HTV/HCR: extrusion, calendaring, cable insulation

Medical-Grade PDMS

Materials intended for medical or food-contact applications must comply with ISO 10993 and FDA guidance, with careful control of catalyst residues and low-molecular-weight extractables.

6. Major Application Areas

Microfluidics and Lab-on-a-Chip Devices: Optical transparency, gas permeability, and ease of molding make PDMS a standard material.

Medical Devices (Non-Long-Term Implantable): Tubing, seals, and housings, subject to regulatory testing.

Electronics and Thermal Management: Electrical insulation and thermally conductive filled formulations.

Industrial Lubrication and Antifoaming: Widely used in chemical processing, food, and personal care.

High-Performance Coatings and Protection: Silicone resins for weather-resistant and insulating coatings.

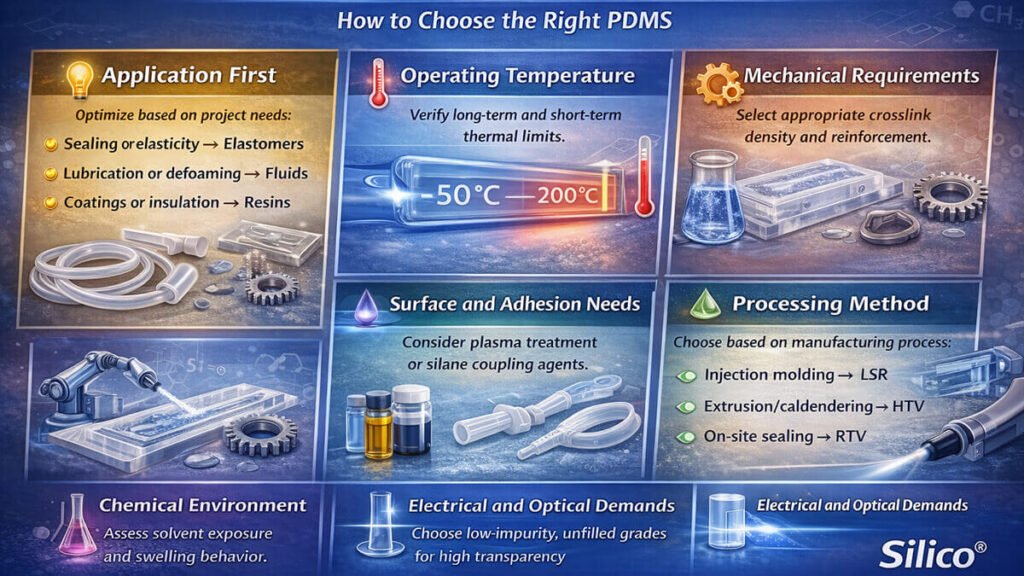

7. Selection Guide: How to Choose the Right PDMS

- Sealing or elasticity → Elastomers

- Lubrication or defoaming → Fluids

- Coatings or insulation → Resins

Operating Temperature

Verify long-term and short-term thermal limits.

Mechanical Requirements

Select appropriate crosslink density and reinforcement.

Surface and Adhesion Needs

Consider plasma treatment or silane coupling agents.

Biocompatibility

For medical or food contact, choose certified grades and addition-cure systems.

Processing Method

Injection molding → LSR

Extrusion/calendering → HTV

On-site sealing → RTV

Chemical Environment

Assess solvent exposure and swelling behavior.

Electrical and Optical Demands

Use low-impurity, unfilled grades for high transparency and low dielectric loss.

8. Processing Considerations and Common Issues

- Air Bubbles: Use vacuum degassing, slow casting, and proper mold venting.

- Catalyst Inhibition: Avoid sulfur- or amine-containing contaminants in platinum-cure systems.

Hydrophobic Recovery: Long-term hydrophilicity requires chemical grafting or surface coatings.

9. Environment, Health, and Regulatory Compliance

PDMS materials demonstrate a strong safety record across industrial and consumer applications. However, medical and food-contact uses require full biocompatibility testing, extractables analysis, and regulatory documentation. Condensation-cure systems should be evaluated for by-product emissions. Environmental fate and lifecycle considerations are increasingly addressed in academic and regulatory studies.

10. Conclusion and Recommended Reading

PDMS remains a cornerstone material across engineering, medical, and industrial sectors due to its chemical stability, thermal resilience, and processing versatility. Successful material selection depends on clearly defined application requirements, compatibility testing, and close collaboration with qualified suppliers. Technical documentation from leading manufacturers and peer-reviewed literature should guide final decisions.

High-quality PDMS materials, such as those offered by Silico®, provide reliable performance supported by detailed technical data, making them suitable for demanding industrial and specialty applications.

Frequently Asked Questions (FAQ)

Q1: Does PDMS swell in water?

A1: No significant swelling occurs in water or polar solvents, but PDMS swells considerably in many nonpolar organic solvents.

Q2: What is the difference between RTV and LSR?

A2: RTV cures at room temperature and is suitable for sealing and repairs, while LSR is designed for high-volume injection molding of precision parts.

Q3: How can PDMS surfaces remain hydrophilic long-term?

A3: Plasma treatment is temporary; long-term solutions require chemical grafting or hydrophilic coatings.

Actionable Recommendations for Engineers and Buyers

- Always request SDS, TDS, biocompatibility data, and batch inspection reports before procurement.

- Conduct pilot trials and compatibility testing for critical applications.

Confirm curing chemistry, degassing procedures, shelf life, and storage conditions with your supplier.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China