Nano Silicone Oil Emulsions vs Conventional Emulsions

- Blog

- June 19, 2020

- 3:57 pm

Silicone oil emulsions have long been valued for their low surface tension, excellent lubricity, thermal stability, and chemical inertness, making them essential functional additives in textiles, personal care, coatings, and industrial formulations.

As end-use industries increasingly demand higher formulation stability, improved substrate penetration, and more refined surface performance, conventional silicone oil emulsions begin to show limitations in certain high-performance applications. Against this backdrop, nano silicone oil emulsions have emerged as a natural evolution of silicone emulsion technology.

At Silico®, continuous research into silicone fluids and emulsion systems reflects this broader industry trend toward finer particle control and more application-oriented performance optimization—without compromising formulation neutrality or compatibility.

Table of Contents

- 1. Conventional Silicone Oil Emulsions: Structure & Applications

- 2. Nano Silicone Oil Emulsions: Definition & Core Properties

- 3. Nano vs. Conventional Emulsions: Key Performance Differences

- 4. Preparation Methods & Critical Parameters

- 5. Industrial Applications & Performance Benefits

- 6. Market Trends & Future Outlook

- 7. Conclusion: Choosing the Right Silicone Oil Emulsion

- 8. Frequently Asked Questions (FAQ)

1. Conventional Silicone Oil Emulsions: Structure & Applications

Conventional silicone oil emulsions are typically composed of silicone fluid, water, and surfactant systems, with dispersed droplet sizes generally in the micron range (1–100 μm). These emulsions are widely used in textile softening, leather finishing, general industrial lubrication, and release agent formulations.

Key Characteristics of Conventional Silicone Oil Emulsions:

- Mature production technology and relatively controlled costs

- Moderate equipment requirements, suitable for large-scale manufacturing

Sensitivity to temperature variation, shear forces, and electrolyte presence

In applications requiring long-term storage stability, high transparency, or extremely uniform surface performance, conventional emulsions often rely on formulation adjustments to compensate for inherent structural limitations.

2. Nano Silicone Oil Emulsions: Definition & Core Properties

Nano silicone oil emulsions are characterized by average droplet sizes typically ranging from 20 to 500 nanometers. The fundamental distinction from conventional emulsions lies not in the silicone oil itself, but in the dispersion state and interfacial architecture within the aqueous phase.

Core Properties of Nano Silicone Oil Emulsions:

- Smaller and more uniform droplet size distribution

- Significantly improved kinetic stability

Transparent or semi-transparent appearance in many formulations

Due to their nanoscale droplets, these emulsions exhibit enhanced surface coverage efficiency, penetration behavior, and film uniformity, making them particularly suitable for advanced and high-value applications.

3. Nano vs. Conventional Emulsions: Key Performance Differences

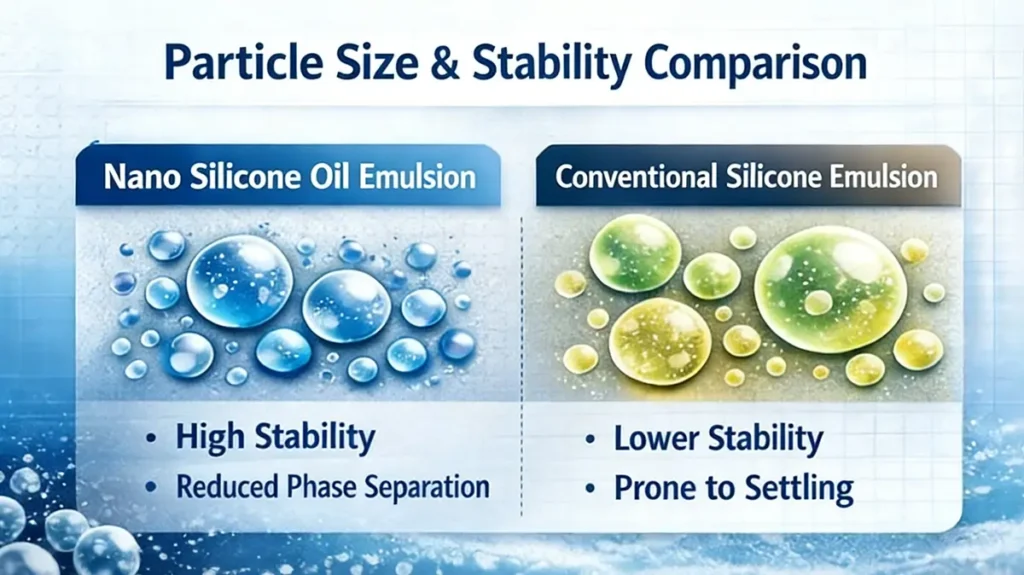

3.1 Droplet Size Distribution and Emulsion Stability

Droplet size distribution plays a decisive role in the storage stability and application consistency of silicone oil emulsions. Nano silicone oil emulsions, benefiting from enhanced Brownian motion and reduced gravitational separation, demonstrate superior resistance to creaming, flocculation, and phase separation.

This advantage is especially relevant for applications requiring highly stable silicone oil emulsions under long storage periods, elevated temperatures, or international transportation conditions.

3.2 Surface Performance and Functional Efficiency

The substantially higher specific surface area of nano-scale droplets allows silicone oil to achieve broader substrate coverage at lower dosages. This is particularly advantageous in:

- Textile fiber softening and lubrication

- Cosmetic formulations aiming for smoother skin feel and improved spreadability

Functional coatings requiring uniform film formation

For formulators seeking low-addition, high-efficiency silicone emulsion solutions, nano emulsions offer a clear performance edge.

4. Preparation Methods & Critical Parameters

Unlike conventional emulsions, nano silicone oil emulsions typically require high-energy emulsification techniques to achieve precise droplet size control.

Common Preparation Methods Include:

- High-pressure homogenization

- Microfluidization

High-shear processing combined with multi-stage homogenization

Key parameters such as emulsifier selection, HLB matching, shear intensity, and process temperature control directly influence final droplet size distribution and emulsion stability.

This explains why “nano silicone oil emulsion preparation process optimization” has become a frequent technical search query across formulation and manufacturing sectors.

5. Industrial Applications & Performance Benefits

5.1 Textile and Fiber Finishing

In advanced textile finishing, nano silicone oil emulsions enable more uniform deposition on fiber surfaces, improving hand feel consistency while reducing issues associated with localized over-application—especially beneficial for high-density or functional fabrics.

5.2 Personal Care and Cosmetic Formulations

For skincare and haircare products, cosmetic-grade silicone oil emulsions demand exceptional clarity, compatibility, and sensory performance. Nano silicone oil emulsions offer advantages in transparency, smooth application, and refined tactile properties, supporting premium product positioning.

Silico® silicone fluid and emulsion technologies are frequently evaluated in such formulation environments, where performance consistency and regulatory adaptability are critical considerations.

5.3 Coatings and Functional Surface Treatments

In construction, automotive coatings, and industrial protection systems, nano silicone oil emulsions facilitate the formation of more continuous and durable silicone-based films, contributing to enhanced water repellency and weather resistance.

6. Market Trends & Future Outlook

Globally, the silicone oil emulsion market is moving toward higher performance, lower energy consumption, and improved environmental compatibility. Nano silicone oil emulsions, supported by advancements in homogenization equipment and process standardization, are steadily expanding beyond niche applications.

As production technologies become more scalable, nano emulsions are expected to penetrate a broader range of industrial formulations while maintaining their advantages in performance-critical applications.

7. Conclusion: Choosing the Right Silicone Oil Emulsion

In summary:

- Conventional silicone oil emulsions remain well-suited for cost-sensitive, well-established applications

Nano silicone oil emulsions provide clear advantages in stability, uniformity, and high-end performance requirements

Selecting the optimal emulsion system should be based on application objectives, formulation complexity, and overall cost-performance balance, rather than particle size alone.

8. Frequently Asked Questions (FAQ)

Q1: Are nano silicone oil emulsions always superior to conventional emulsions?

Not necessarily. Nano emulsions excel in high-performance applications, while conventional emulsions remain practical and cost-effective for many standard uses.

Q2: Do nano silicone oil emulsions offer better long-term stability?

Yes, their smaller droplet size generally improves resistance to phase separation, especially under thermal or mechanical stress.

Q3: Are nano silicone oil emulsions suitable for cosmetic formulations?

They are particularly well-suited for cosmetic and personal care applications requiring clarity, smooth sensory feel, and formulation compatibility.

Q4: Is the production cost of nano silicone oil emulsions significantly higher?

Production costs are typically higher due to advanced equipment and energy input, but this can be offset by lower usage levels and enhanced performance.

Q5: Can suppliers like Silico® provide both conventional and nano silicone oil emulsion solutions?

Many established silicone material suppliers, including Silico®, develop both conventional and nano-scale emulsion technologies to support diverse application needs and formulation strategies.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China