PV501 Vinyl-Terminated Polymethylvinylsiloxane (Vi-PMVS)

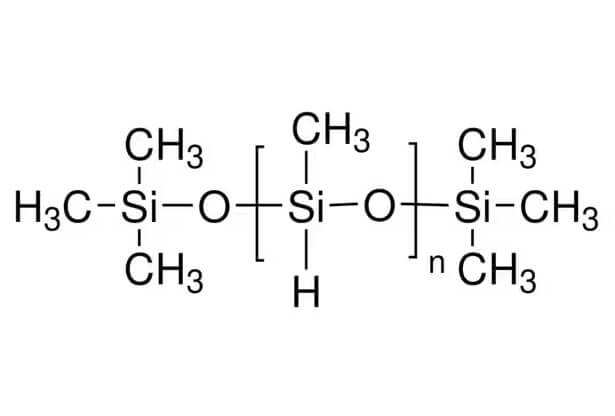

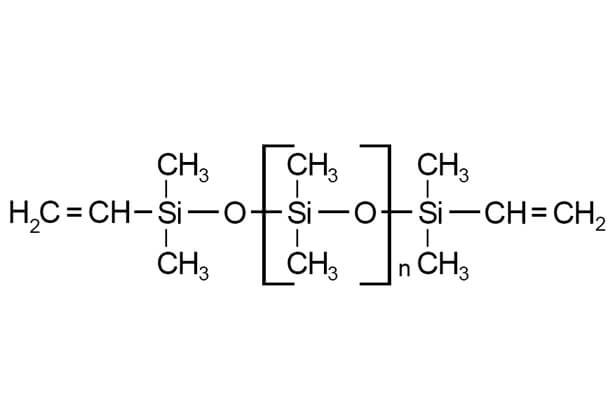

Silico®- PV501 Vinyl-Terminated Polymethylvinylsiloxane (Vi-PMVS) (CAS 68083-19-2) is a vinyl-terminated polymethylvinylsiloxane fluid with vinyl groups on the chain ends and backbone. It is a clear, viscous liquid offering high reactivity, flexibility, and compatibility, widely used in LSR, adhesives, potting compounds, and encapsulants.

PV501 Product Features

Silico®-PV501 VPMVS is a vinyl-terminated polymethylvinylsiloxane fluid featuring vinyl groups at both ends of the polymer chain and within the siloxane backbone.

It is a transparent, colorless, viscous liquid, providing excellent flexibility, high reactivity for addition-curing reactions, and superior compatibility with various organic materials.

Silico®-PV 501 is primarily used in producing high-performance addition-cure liquid silicone rubber (LSR), electronic potting compounds, adhesives, and encapsulants.

It offers outstanding thermal stability, radiation resistance, aging resistance, and strong mechanical properties.

Its vinyl content and viscosity can be customized according to application needs, ensuring flexible formulation design.

Technical Specifications:

| Property | Silico®-VPMVS-1000 | Silico®-VPMVS-3000 |

|---|---|---|

| Appearance | Colorless transparent liquid | Colorless transparent liquid |

| Viscosity (25°C, mPa·s) | 800–1200 | 2500–3500 |

| Vinyl Content (mol/100g) | 0.08–0.10 | 0.04–0.06 |

| Refractive Index (25°C) | 1.400–1.410 | 1.400–1.410 |

| Volatile Content (150°C, 3h, %) | ≤1.5 | ≤1.5 |

| CAS Number | 68083-19-2 | 68083-19-2 |

Applications

Production of addition-curing liquid silicone rubber (LSR)

Electronic potting, sealing, bonding, and coating

High-performance heat-resistant silicone elastomers

Optical materials, adhesives, encapsulants

Usage & Dosage

Silico®-PV 501 VPMVS can be used directly or mixed with crosslinkers and platinum catalysts to prepare addition-cure silicone systems. The dosage depends on the vinyl content and the final application requirements.

Packaging & Storage

Avoid contamination with nitrogen, phosphorus, sulfur compounds, peroxide, heavy metals (like tin, lead, cadmium), which can poison the platinum catalyst and inhibit curing.

Store in a cool, dry place in sealed containers.

Shelf life: 12 months in unopened packaging.

Packaging: 25kg, 50kg, 200kg drums or 1000kg IBC tanks.

Transport as non-hazardous goods.

All technical data provided is based on current knowledge and experience. Users must test product suitability for intended applications.

No warranties are expressed or implied. Silico® assumes no liability for incidental or consequential damages.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.