Epoxy Silanes

Epoxy Silanes

Epoxy silanes are bifunctional compounds with reactive epoxy and hydrolyzable alkoxy groups. As effective epoxy silane coupling agents, they enhance adhesion between epoxy, polyurethane, acrylic, silicone resins and glass, metal, dyes, fillers, minerals. Widely used in coatings, adhesives, and sealants, they improve durability and performance.

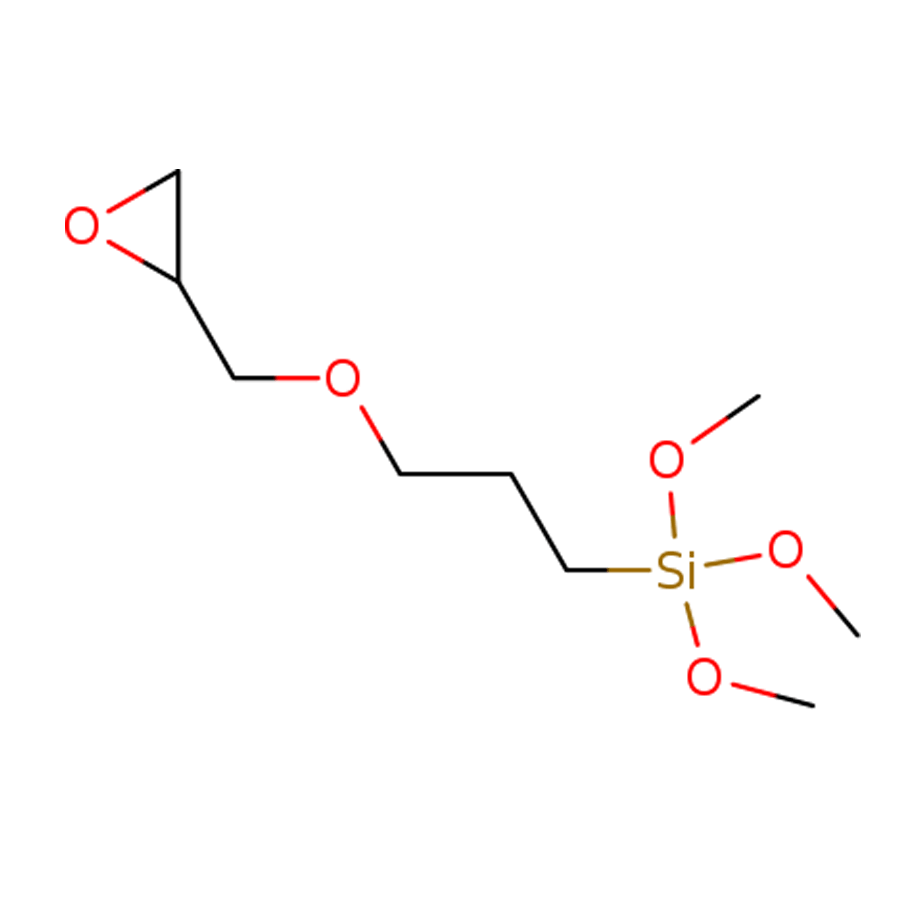

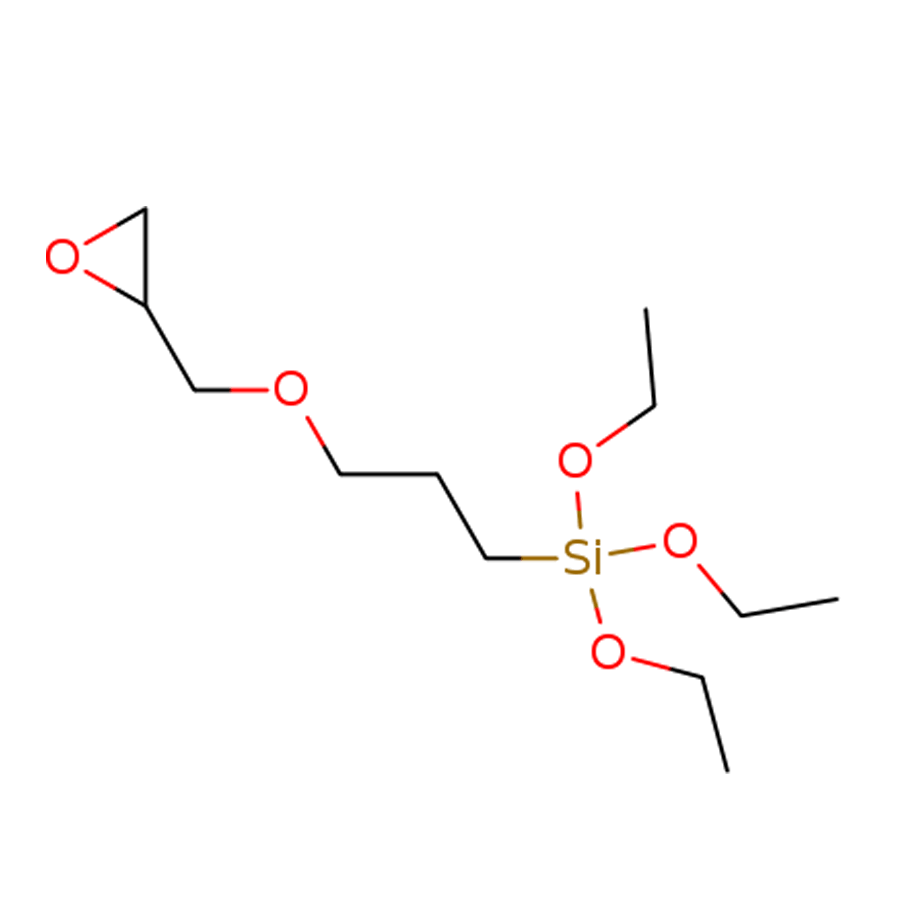

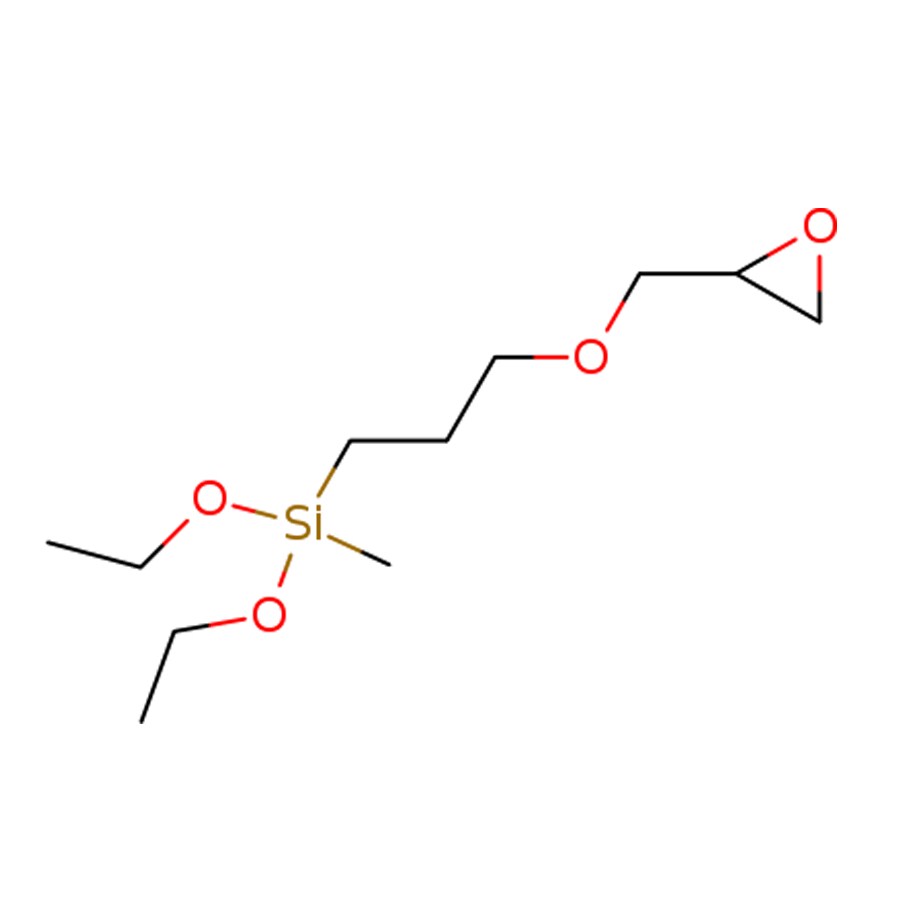

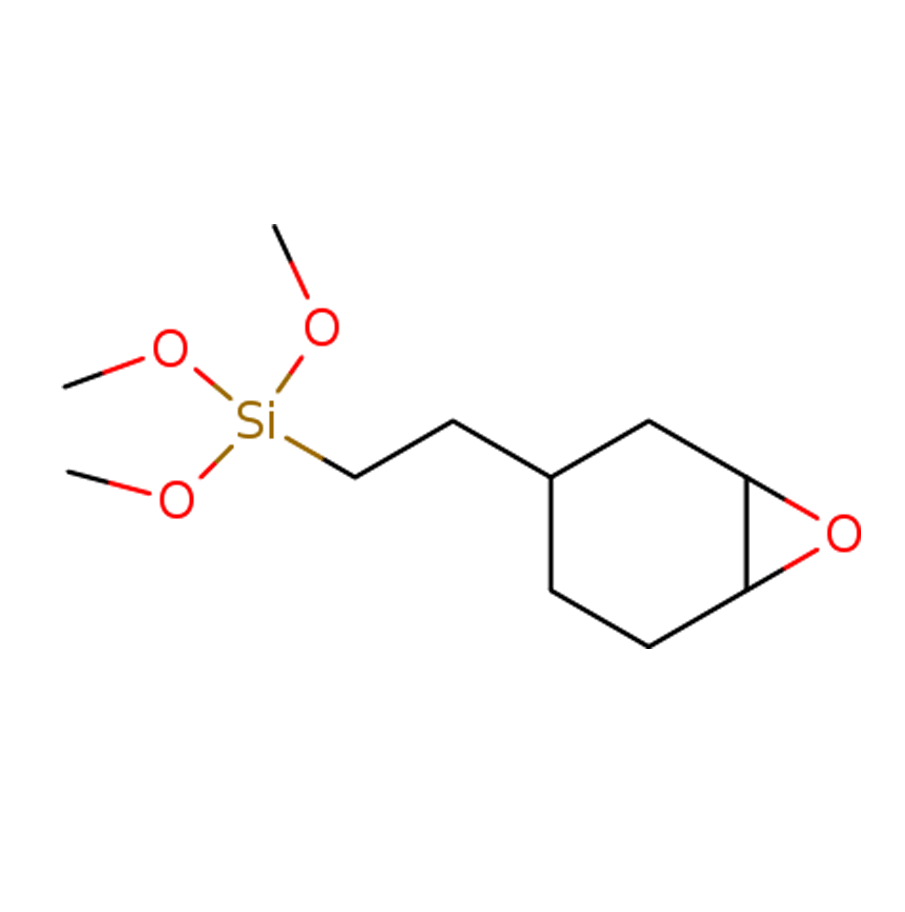

| CAS NO. | Product Name |

| 2530-83-8 | 3-Glycidoxypropyltrimethoxysilane |

| 2602-34-8 | 3-Glycidoxypropyltriethoxysilane |

| 2897-60-1 | 3-(2,3-Epoxypropoxypropyl) methyldiethoxysilane |

| 3388-04-3 | 2-(3,4-Epoxycyclohexyl) ethyltrimethoxysilane |

Key Features of Epoxy Silanes

Epoxy silane offers superior adhesion and non-yellowing properties. Compared to amino silanes, epoxy silane is more stable and does not affect the final product’s color. This makes epoxy silane an ideal adhesion promoter for coatings, sealants, and adhesives, enhancing durability and weather resistance.

Development Status of Epoxy Silanes

At Silico, we offer a wide range of epoxy silanes, including standard epoxy and alkoxy silanes, as well as specialized bifunctional epoxy siloxanes. As a leader in epoxy silane production, Silico‘s experts have spent the past decade developing innovative epoxy silane products to meet the growing demand for high-performance materials across industries.

Functions & Applications of Epoxy Silanes

Silico epoxy silanes are widely used as adhesion promoters in the coatings, adhesives, and sealants industries, improving adhesion, filler dispersion, and corrosion resistance. They are especially important in marine coatings.

In addition to traditional solvent-based systems, epoxy silanes are also suitable for eco-friendly waterborne coatings, which are expected to grow in market share.

In the semiconductor and electronics industries, Silico epoxy silanes are increasingly used in electronic packaging, enhancing the electrical properties of epoxy-based compounds. Low-chlorine epoxy silanes also improve the safety and corrosion resistance of semiconductors and PCBs.

Packaging Specifications

Silico® Prouducts

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

How to Select Epoxy Silanes?

When selecting an epoxy silane, consider these factors:

- Compatibility: Choose an epoxy silane that matches your resin system (e.g., epoxy for epoxy resins, urethane for polyurethanes).

- Substrate Bonding: Epoxy silanes help bond inorganic materials (like glass or metals) with organic polymers.

- Moisture Sensitivity: Ensure the silane works with the moisture level of your fillers.

- Performance Needs: Choose based on required attributes like adhesion strength, water resistance, or electrical properties.

- Application: Pick a silane suited for your specific application, such as coatings, adhesives, or sealants.

Consult with suppliers for tailored recommendations.