What Are Silicone Oil Emulsions & How Do They Work?

- Blog

- October 7, 2021

- 10:15 am

Silicone oil emulsions play a critical role in modern formulation science, serving as a bridge between hydrophobic silicone fluids and water-based systems. Across industries such as textile finishing, personal care, construction chemicals, coatings, and industrial manufacturing, they enable formulators to incorporate silicone functionality into aqueous processes without sacrificing performance.

As a leading silicone solution provider, Silico® focuses on developing high-performance silicone oil emulsions that allow formulators to achieve reliable surface modification, process efficiency, and regulatory-friendly water-based formulations.

By converting silicone oils into stable, water-dispersible systems, silicone emulsions significantly improve handling safety, application uniformity, and environmental compatibility, making them a preferred alternative to solvent-based silicone delivery systems.

Table of Contents

- 1. Understanding Silicone Oil: Chemistry & Key Traits

- 2. Defining Silicone Oil Emulsions

- 3. How Silicone Oil Emulsions Work: Mechanism & Stabilization

- 4. Types & Classification of Silicone Emulsions

- 5. Key Properties & Performance Features

- 6. How Silicone Emulsions Are Made

- 7. Primary Industrial & Commercial Applications

- 8. Benefits of Using Silicone Oil Emulsions

- 9. Selection Tips: How to Choose the Right Emulsion

- 10. Conclusion

1. Understanding Silicone Oil: Chemistry & Key Traits

Silicone oils are typically based on polydimethylsiloxane (PDMS) or related siloxane polymers composed of alternating silicon–oxygen backbones with organic side groups. This molecular architecture provides a combination of properties rarely matched by organic polymers:

- Extremely low surface tension, enabling excellent wetting and water repellency

- Outstanding thermal and oxidative stability

- Chemical inertness, ensuring broad formulation compatibility

High flexibility and lubricity across a wide viscosity range

Despite these advantages, silicone oils are inherently immiscible with water, which restricts their direct use in aqueous systems and creates the need for silicone oil emulsions.

2. Defining Silicone Oil Emulsions

A silicone oil emulsion is a stabilized system in which finely divided silicone oil droplets are uniformly dispersed in water with the aid of emulsifiers. This transformation enables water-insoluble silicone fluids to be used in water-based silicone emulsion formulations without compromising functional performance.

The emulsifier forms a protective interfacial layer around each droplet, preventing separation and ensuring long-term stability during storage, transportation, dilution, and application.

3. How Silicone Oil Emulsions Work: Mechanism & Stabilization

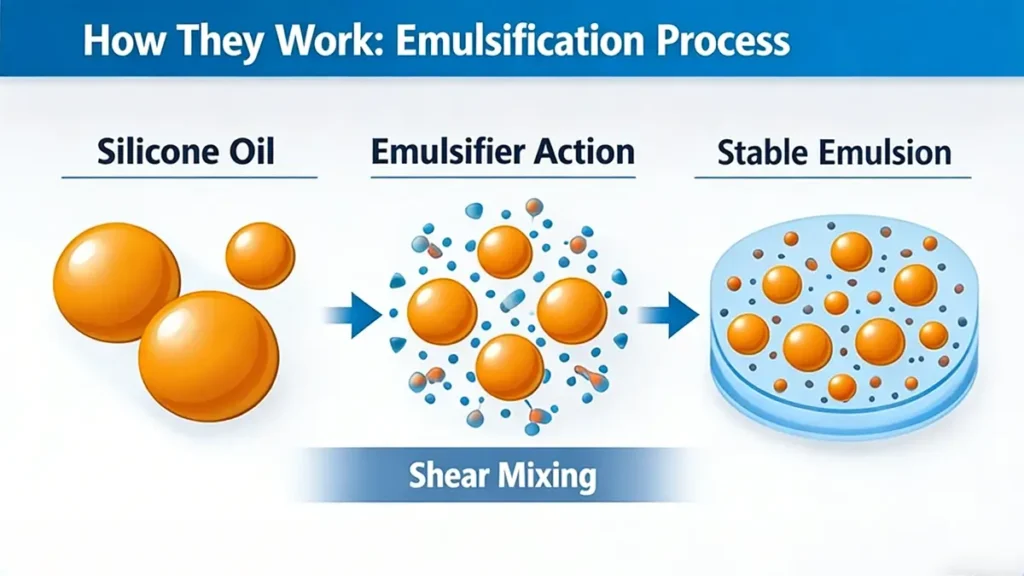

Emulsification Fundamentals

- Silicone oil is hydrophobic and does not mix with water naturally

- Emulsifiers reduce interfacial tension between oil and water phases

High-shear mechanical energy breaks silicone oil into fine droplets

This process produces a stable silicone dispersion suitable for industrial-scale applications.

Mechanisms of Stability

Stability in silicone oil emulsions is achieved through interfacial film formation. Emulsifier molecules create a continuous protective layer around droplets, resisting coalescence and phase separation.

At this stage, formulation expertise—such as that applied in Silico® silicone emulsion technologies—is critical to balancing droplet size, emulsifier chemistry, and resistance to shear, heat, and dilution.

Key influencing factors include:- Droplet size distribution

- Emulsifier structure and concentration

Electrostatic and steric stabilization mechanisms

4. Types & Classification of Silicone Emulsions

🔹 By Particle Size

- Macro-emulsions: 0.1–1 µm, milky appearance

- Micro-emulsions: <0.4 µm, clear or translucent

🔹 By Emulsifier Type

- Non-ionic emulsions (widely used for broad compatibility)

- Anionic emulsions

- Cationic emulsions (strong affinity for fibers and charged substrates)

Emulsifier selection directly affects formulation compatibility and end-use behavior.

5. Key Properties & Performance Features

✦ Water Dilutability & Ease of Use

✦ Stability & Shelf Life

✦ Surface Modification

✦ Functional Versatility

They can deliver softness, anti-static behavior, abrasion resistance, and release properties depending on formulation design.

6. How Silicone Emulsions Are Made

The manufacturing process typically includes:

- Silicone oil selection based on viscosity and molecular structure

- Emulsifier system design for stability and compatibility

- High-shear emulsification to achieve controlled droplet size

Stabilization and quality control

Precise control of these parameters determines the final emulsion’s performance in real-world applications.

7. Primary Industrial & Commercial Applications

🧵 Textile & Fabric Finishing

🧴 Personal Care & Cosmetics

🏭 Industrial Lubrication & Release Agents

🧱 Construction Materials & Coatings

📊 Additional Uses

Include defoamers, antistatic finishes, automotive polishes, and specialty coatings.

8. Benefits of Using Silicone Oil Emulsions

✔ Water-based, safer handling

✔ High efficiency at low dosage

✔ Broad functional performance

✔ Supports low-VOC and environmentally friendly formulations

9. Selection Tips: How to Choose the Right Emulsion

- Required droplet size and silicone viscosity

- Compatibility with other formulation components

- Stability under storage and processing conditions

- Substrate interaction and deposition efficiency

10. Conclusion

Silicone oil emulsions are engineered delivery systems that enable silicone chemistry to perform effectively in water-based environments. Through proper selection and formulation, they provide reliable surface modification, process efficiency, and long-term stability.

Backed by application-driven development and formulation expertise, Silico® silicone oil emulsions help engineers and formulators achieve consistent, high-performance results across industrial, commercial, and specialty applications.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China