Silico MF2010-350 cSt Silicone Fluid

Silico® MF2010-350 cSt Silicone Fluid is a high-purity linear PDMS silicone oil with 350 cSt viscosity at 25 °C. It offers stable medium-high viscosity, excellent thermal resistance, low surface energy, and chemical inertness for industrial, mechanical, electrical, and process applications requiring consistent rheology and material compatibility.

Introduction

Industrial-Grade Medium-High Viscosity PDMS Silicone Oil (Non-Food Grade)

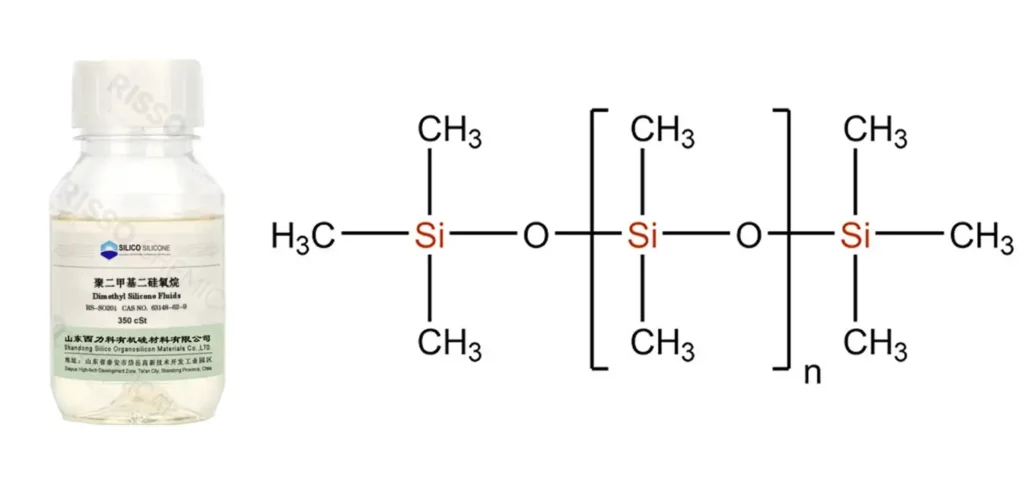

Silico® MF2010-350 cSt Silicone Fluid is a high-purity, linear polydimethylsiloxane (PDMS) silicone oil with a nominal kinematic viscosity of 350 cSt at 25 °C.

It is specifically designed for industrial applications requiring stable medium-high viscosity, excellent thermal resistance, low surface energy, and long-term chemical inertness.

This product is non-food grade and intended exclusively for industrial, mechanical, electrical, and process applications where consistent rheological behavior and material compatibility are critical.

Typical Physical Properties

| Property | Typical Value |

|---|---|

| Chemical Name | Polydimethylsiloxane (PDMS) |

| CAS Number | 63148-62-9 |

| Appearance | Clear, colorless liquid |

| Kinematic Viscosity (25 °C) | 350 cSt |

| Specific Gravity (25 °C) | ~0.97 |

| Refractive Index (25 °C) | ~1.403 |

| Surface Tension (25 °C) | ~21 mN/m |

| Flash Point (Closed Cup) | > 300 °C |

| Auto-Ignition Temperature | > 400 °C |

| Pour Point | ~-50 °C |

| Solubility | Insoluble in water; soluble in many organic solvents |

| Thermal Stability | Excellent |

| Dielectric Properties | High dielectric strength and resistivity |

Key Performance Advantages

-

Controlled Medium-High Viscosity (350 cSt)

Provides enhanced damping performance, reduced flow volatility, and improved mechanical stability. Excellent Thermal Stability

Maintains viscosity and performance over a wide operating temperature range.Low Surface Tension & Hydrophobicity

Enables effective wetting, release, and surface protection properties.Outstanding Chemical Inertness

Resistant to oxidation and compatible with most plastics, elastomers, and metals.Low Volatility & High Flash Point

Suitable for closed systems and elevated-temperature industrial environments.Superior Dielectric Properties

Ideal for electrical insulation and damping fluid applications.

Typical Applications

Silico® MF2010-350 cSt Silicone Fluid is widely used in:

Release Agents for rubber molding, plastic processing, and metal casting

Damping & Vibration Control Fluids in precision instruments and mechanical systems

Lubrication of Plastics and Elastomers where mineral oils are unsuitable

Heat Transfer & Thermal Bath Fluids requiring viscosity stability

Electrical Insulation & Dielectric Media in electronic and electrical components

Surface Treatment, Polishes & Specialty Coatings

Process Additives & Anti-Foam Formulations

These applications benefit from the inherent PDMS advantages of low surface energy, thermal endurance, and long service life.

Performance Advantages at 350 cSt

Compared with lower-viscosity silicone fluids, Silico® MF2010-350 offers:

Improved mechanical damping and vibration control

Greater resistance to shear thinning

More stable film formation on treated surfaces

Enhanced durability in continuous-operation systems

This makes it particularly suitable for precision equipment, industrial damping systems, and high-performance surface treatments.

Packaging and Storage

Packaging: Available in drums, pails, or bulk supply upon request

Storage: Store in sealed original containers in a cool, dry, well-ventilated area

Shelf Life: ≥ 24 months under recommended storage conditions

Handling: Avoid contamination; refer to SDS for detailed safety guidance

Documents

Why Choose Silico® MF2010-350 cSt Silicone Fluid?

Silico® MF2010-350 cSt Silicone Fluid is a medium-high viscosity PDMS silicone oil engineered for demanding industrial applications. It provides stable damping, controlled flow, and excellent thermal and chemical resistance.

Its low surface tension, hydrophobic nature, and strong dielectric properties make it ideal for release agents, lubrication, surface treatment, and electrical insulation. With low volatility and high flash point, it ensures long-lasting performance in mechanical and process systems.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.