Silico MF2010-10,000 cSt Silicone Fluid

Introduction

Ultra High-Viscosity PDMS Silicone Oil for Industrial Applications

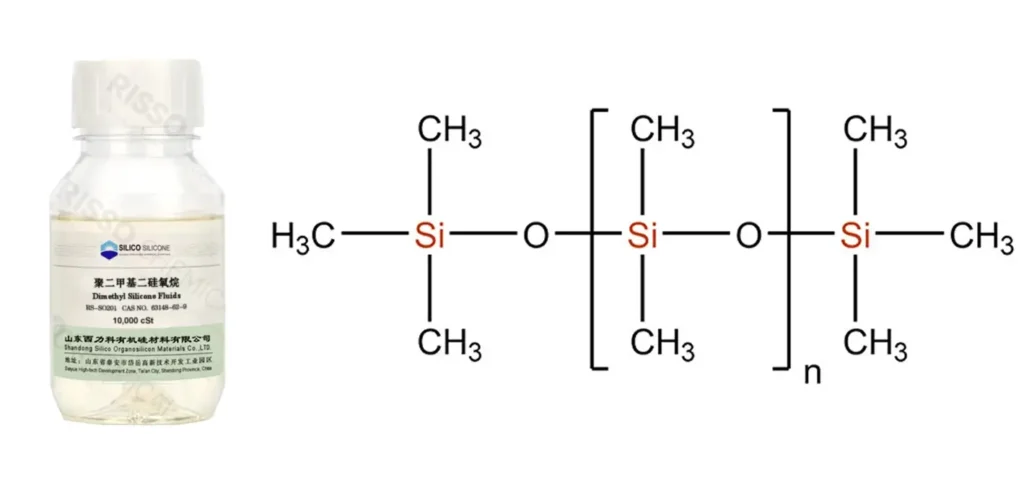

Silico® MF2010‑10,000 cSt Silicone Fluid is a high-purity, linear polydimethylsiloxane (PDMS) designed for ultra-high viscosity applications in industrial and engineering systems. With a nominal viscosity of 10,000 cSt at 25 °C, it provides thick, durable fluid films for mechanical damping, heavy-duty lubrication, thermal management, and dielectric insulation.

As part of the Silico® MF2010 high-viscosity series, this fluid combines excellent thermal stability, low volatility, and chemical inertness, making it ideal for long-term, demanding industrial operations.

Typical Physical Properties

| Property | Typical Value |

|---|---|

| Chemical Name | Polydimethylsiloxane (PDMS) |

| CAS Number | 63148‑62‑9 |

| Appearance | Clear, colorless viscous liquid |

| Kinematic Viscosity (25 °C) | 10, 000 cSt |

| Density (25 °C) | ~0.975 g/cm³ |

| Refractive Index (25 °C) | ~1.403 |

| Surface Tension (25 °C) | ~21.5 mN/m |

| Flash Point (Closed Cup) | ≥ 320 °C |

| Pour/Freezing Point | ~ –50 °C |

| Solubility | Insoluble in water; miscible with most organic solvents |

| Thermal Stability | Excellent |

| Dielectric Properties | High resistivity, stable insulation |

Key Performance Advantages

Ultra-High Viscosity (10 000 cSt) — Ensures long-lasting film thickness for lubrication, damping, and surface protection.

Thermal & Oxidative Stability — Maintains consistent viscosity and performance across wide temperature ranges.

Low Surface Tension & Hydrophobicity — Promotes superior wetting, release, and water-repellent behavior.

Chemical Inertness — Resistant to oxidation and compatible with metals, plastics, and elastomers.

Low Volatility & High Flash Point — Reduces evaporation losses, extending operational life.

Excellent Dielectric Properties — Stable electrical insulation for industrial and electronic systems.

Typical Applications

Silico® MF2010‑10,000 cSt Silicone Fluid is widely used in:

Mechanical damping and vibration control systems

High-viscosity lubrication for seals, bearings, and heavy-load machinery

Mold release agents for rubber, plastics, and metal die casting

Thermal interface fluids and heat transfer applications

Electrical insulation and dielectric media

Surface treatment, coatings, and specialty fluid formulations

These applications leverage the fluid’s ultra-high viscosity, hydrophobicity, thermal resilience, and chemical stability for reliable, long-term performance.

Packaging and Storage

Packaging: 190 kg steel drums or 950 kg IBC containers

Storage Conditions: Store in a cool, dry, well-ventilated area. Keep containers tightly sealed. Avoid contact with water, strong acids, bases, and oxidizing agents.

Safety Note: Non-toxic and low volatility, but handle according to standard chemical safety protocols.

Documents

Why Choose Silico® MF2010‑10,000 cSt Silicone Fluid?

Silico® MF2010-10,000 cSt Silicone Fluid is an ultra-high viscosity PDMS silicone oil formulated for industrial systems that require exceptionally thick fluid films and extended service life. Its high viscosity supports stable damping, load bearing, and shear resistance in precision and heavy-duty machinery.

This grade delivers consistent performance in extreme thermal conditions with minimal volatility and excellent oxidation resistance. The fluid’s low surface energy and chemical inertness enhance wetting, release behavior, and surface interaction in complex processing environments. Silico® MF2010-10,000 is ideal for engineers and formulators seeking a robust, high-viscosity silicone solution for critical industrial, mechanical, and thermal applications.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.