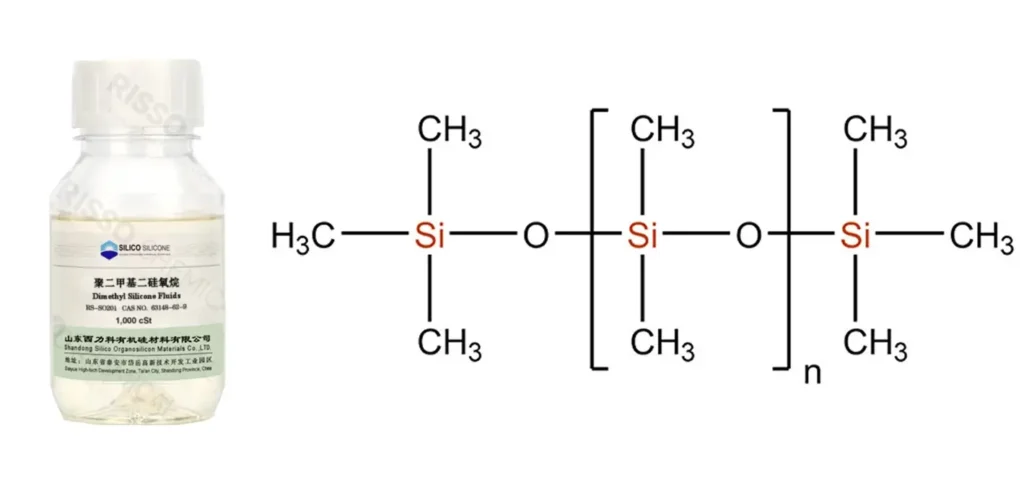

Silico MF2010-1000 cSt Silicone Fluid

Silico® MF2010‑1,000 cSt Silicone Fluid is a high-purity PDMS oil with 1000 cSt viscosity at 25 °C. It provides thermal stability, chemical inertness, low volatility, and excellent dielectric performance, ideal for industrial, electronic, and specialty applications. Its thick but flowable nature ensures lubrication, damping, anti-foaming, and mold release with consistent performance.

Introduction

Silico® MF2010‑1,000 cSt Silicone Fluid is a premium, high-purity polydimethylsiloxane (PDMS) silicone oil with a kinematic viscosity of approximately 1,000 cSt at 25 °C. This high-viscosity silicone fluid exhibits exceptional thermal stability, chemical inertness, low volatility, and superior dielectric performance, making it ideal for a wide range of industrial, electronic, and specialty formulation applications.

Its thick, yet flowable nature provides robust lubrication, damping, anti-foaming, and mold release capabilities, while maintaining consistent performance across demanding operating conditions.

Typical Physical Properties

| Property | Typical Value |

|---|---|

| Chemical Name | Polydimethylsiloxane (PDMS) |

| Brand & Model | Silico® MF2010‑1,000 cSt Silicone Fluid |

| CAS Number | 63148‑62‑9 / 9006‑65‑9 |

| Appearance | Clear, colorless liquid |

| Kinematic Viscosity (25 °C) | ~1,000 cSt |

| Density (25 °C) | ~0.970 g/cm³ |

| Refractive Index (25 °C) | ~1.403 |

| Flash Point | > 300 °C |

| Fire Point | > 400 °C |

| Pour Point | ~‑50 °C |

| Surface Tension | ~21 mN/m |

| Volatility | Extremely low |

| Toxicity | Essentially non-toxic |

Key Performance Advantages

🔹 Exceptional Thermal Stability

Maintains consistent viscosity and chemical stability across a wide temperature range (‑50 °C to +200 °C and beyond).

High flash and fire points enable safe use in industrial and electronic applications.

🔹 Outstanding Chemical Inertness

Resistant to oxidation, hydrolysis, and chemical degradation.

Compatible with metals, plastics, and elastomers in demanding environments.

🔹 Superior Dielectric & Electrical Insulation

- Low electrical conductivity and high dielectric strength make it an ideal dielectric insulating fluid for transformers, capacitors, and electronics.

🔹 Low Surface Tension & Anti-Foaming

Enhances spreadability and flow in formulations.

Reduces foam formation in industrial processes and chemical formulations.

🔹 Low Volatility & Long-Term Stability

- Minimal evaporation maintains fluid integrity in open systems or high-temperature applications.

Typical Applications

⚙️ Industrial & Mechanical

Precision damping and shock-absorbing fluids

High-viscosity industrial lubricants

Pneumatic and hydraulic systems requiring stable fluid performance

🧪 Chemical Processing & Formulation

Mold release agent for plastics, rubber, and metal casting

Anti-foaming additive in specialty formulations

Surface treatment and flow-control additive in coatings and lubricants

🔌 Electrical & Electronics

Dielectric insulating fluids

Thermal interface materials for electronics

Damping fluids in precision instruments

🚿 Surface Treatment & Coatings

Specialty polishes and protective coatings

Water-repellent and finishing applications for furniture, automotive, and textiles

Packaging and Storage

Packaging: 190 kg steel drums or 950 kg IBC containers

Storage Conditions: Store in a cool, dry, well-ventilated area. Keep containers tightly sealed. Avoid contact with water, strong acids, bases, and oxidizing agents.

Safety Note: Non-toxic and low volatility, but handle according to standard chemical safety protocols.

Documents

Why Choose Silico® MF2010‑1,000 cSt Silicone Fluid?

Silico® MF2010‑1,000 cSt Silicone Fluid is a high‑purity PDMS silicone oil engineered for demanding industrial and specialty applications. Its 1,000 cSt viscosity provides enhanced damping, lubrication, and stable flow over a wide temperature range, with excellent thermal resistance, low volatility, and long‑term chemical inertness.

The fluid’s low surface tension and strong dielectric performance support superior wetting, release, and electrical insulation in heat transfer, precision mechanisms, and high‑load systems. These characteristics make MF2010‑1,000 a dependable choice for engineers and formulators seeking consistent rheology, durability, and reliable performance in complex applications.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.