PDMS Silicone Fluid Surface Treatment & Functional Modification

- Blog

- July 23, 2020

- 9:46 am

PDMS silicone fluid is a key material in surface engineering, valued for its low surface energy, chemical stability, and thermal performance. However, its intrinsic hydrophobicity often limits wettability control and interfacial adhesion. This article outlines major PDMS silicone fluid surface treatment and modification technologies, including plasma and UV/ozone activation, chemical functionalization, polymer grafting, and nanostructured surface design. These approaches enable the transformation of PDMS surfaces from hydrophobic to hydrophilic or multifunctional states, supporting advanced applications in microfluidics, electronic encapsulation, and functional coatings.

Table of Contents

- 1. Introduction: Why Surface Modification of PDMS Silicone Fluid Is Critical

- 2. Fundamental Surface Characteristics of PDMS Silicone Fluid

- 3. Physical Surface Treatment Technologies for PDMS Silicone Fluid

- 4. Chemical Surface Modification Strategies for Long-Term Stability

- 5. From Hydrophobicity to Functional Surface Design

- 6. Representative Application Scenarios

- 7. Conclusion: Future Directions in PDMS Silicone Fluid Surface Engineering

1. Introduction: Why Surface Modification of PDMS Silicone Fluid Is Critical

Polydimethylsiloxane (PDMS) silicone fluid is one of the most representative organosilicon materials, valued for its low surface energy, chemical inertness, wide operating temperature range, and excellent electrical insulation performance. These intrinsic properties have enabled extensive use of PDMS silicone fluid in:

- Microfluidic and lab-on-a-chip devices

- Electronic encapsulation and protection

- Functional and release coatings

- Lubrication and interface control systems

Biomedical and diagnostic engineering

However, the inherently stable hydrophobic surface of PDMS can also limit its performance in applications that require controlled wettability, strong interfacial adhesion, or multifunctional surface behavior. As a result, surface treatment and modification technologies have become essential for transforming PDMS silicone fluid interfaces from simple hydrophobic surfaces into hydrophilic, superhydrophobic, anti-fouling, anti-icing, or chemically functionalized surfaces, while preserving bulk material properties.

2. Fundamental Surface Characteristics of PDMS Silicone Fluid

- Surface free energy typically below 21 mN/m

- Static water contact angles in the range of 95°–110°

Excellent moisture resistance and release behavior

- Liquid spreading in microchannels

- Biomolecule immobilization

- Coating and adhesive bonding

Long-term interfacial stability

Consequently, PDMS surface modification strategies primarily focus on altering surface chemistry, regulating surface energy, or constructing micro–nano hierarchical structures to meet application-specific performance requirements.

3. Physical Surface Treatment Technologies for PDMS Silicone Fluid

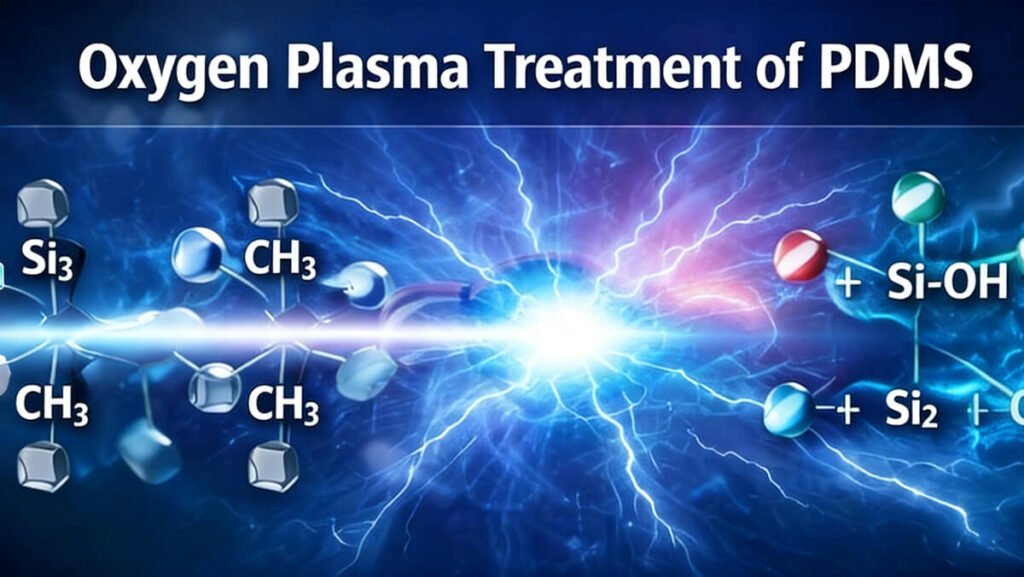

3.1 Oxygen Plasma Surface Treatment

Oxygen plasma treatment is one of the most widely applied techniques for PDMS surface activation. High-energy plasma breaks Si–CH₃ bonds at the surface and introduces silanol (Si–OH) functional groups, rapidly converting PDMS from hydrophobic to highly hydrophilic.

This method is particularly critical in microfluidic device fabrication, where PDMS must bond reliably to glass or polymer substrates. However, plasma-treated PDMS surfaces often exhibit hydrophobic recovery over time due to molecular chain rearrangement, making post-treatment stabilization or chemical grafting essential for long-term performance.

3.2 UV/Ozone (UV/O₃) Surface Oxidation

UV/ozone treatment generates reactive oxygen species that oxidize the PDMS surface, forming a thin silica-like layer enriched with polar functional groups. Compared with plasma treatment, UV/O₃ processing offers:

- Improved treatment uniformity

- Milder reaction conditions

Reduced surface damage

These advantages make UV/O₃ oxidation particularly suitable for biointerfaces, optical components, and precision surface engineering applications.

3.3 Thermal Treatment and Surface Migration Behavior

Under controlled thermal conditions, low-molecular-weight PDMS chains may migrate toward or away from the surface, forming gradient interfacial layers. This phenomenon plays a key role in:

- Long-term lubrication stability

- Friction and wear regulation

Controlled surface renewal systems

Silico® PDMS silicone fluids, with tightly controlled molecular weight distribution, are often selected for such applications to ensure predictable surface migration behavior and consistent interfacial performance.

4. Chemical Surface Modification Strategies for Long-Term Stability

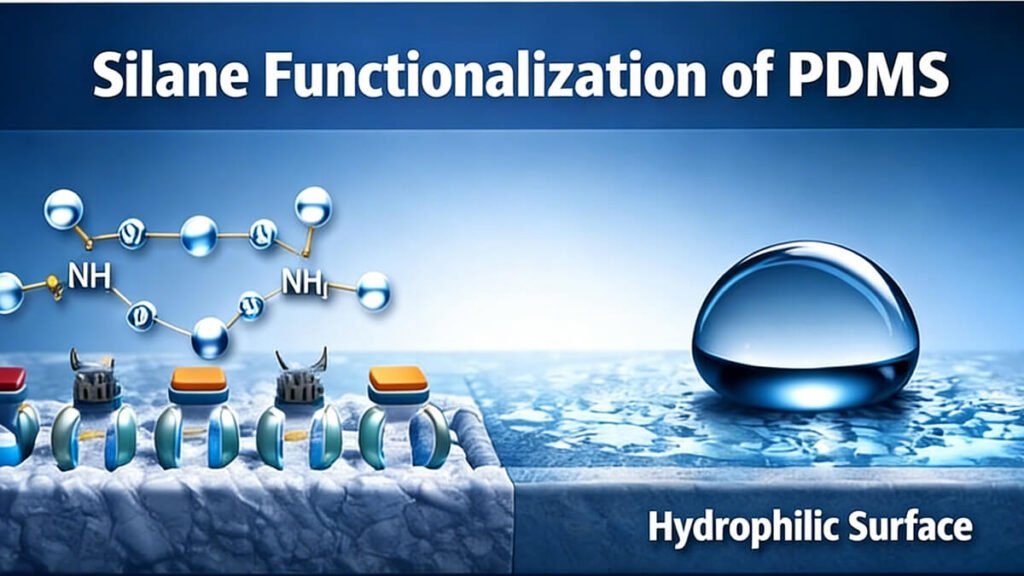

4.1 Silane Coupling Agents and Functionalization

- Interfacial adhesion strength

- Coating durability

Compatibility with inorganic substrates

This approach is widely used in electronic packaging, composite interfaces, and advanced coating systems.

4.2 Polymer Grafting and Functional Surface Coatings

Grafting hydrophilic or functional polymers—such as polyethylene glycol (PEG), polyvinyl alcohol (PVA), or zwitterionic polymers—onto PDMS surfaces effectively reduces nonspecific adsorption and improves biocompatibility.

Such surface modification strategies are extensively applied in medical devices, diagnostic chips, and drug delivery systems utilizing PDMS-based materials.

4.3 Nanofiller-Assisted Surface Engineering

- Anti-fouling coatings

- Oil–water separation

Functional membranes and filters

5. From Hydrophobicity to Functional Surface Design

5.1 Superhydrophobic and Low-Adhesion Surfaces

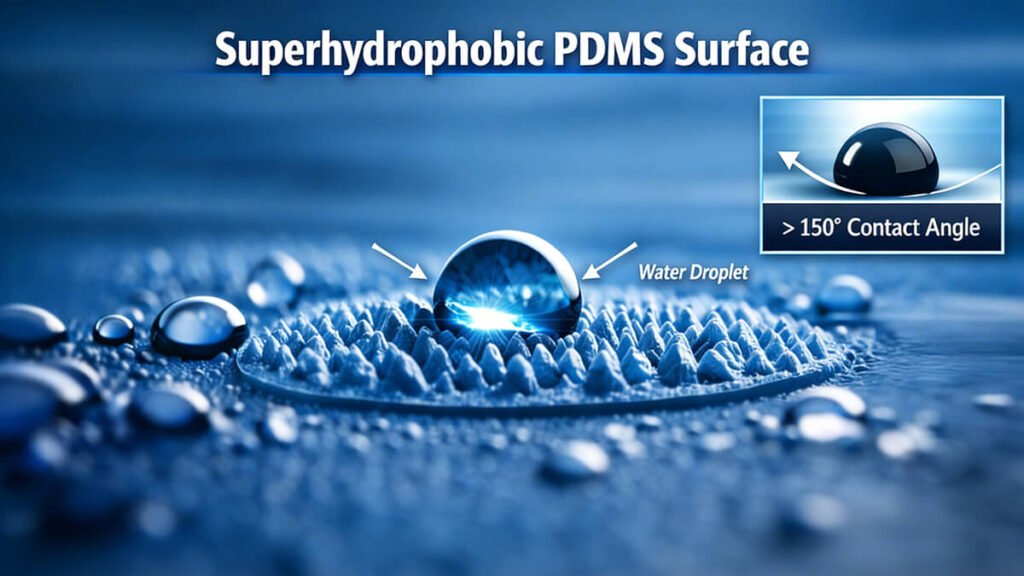

By integrating micro–nano structural engineering with optimized PDMS silicone fluid formulations, surfaces with water contact angles exceeding 150° and extremely low sliding angles can be achieved. These surfaces exhibit excellent self-cleaning behavior and resistance to contamination.

5.2 Anti-Icing and Anti-Frost PDMS Interfaces

PDMS-based surfaces incorporating lubricating layers or elastic architectures can significantly reduce ice adhesion strength and delay ice nucleation. These technologies are receiving increasing attention in aerospace, renewable energy, and cold-environment infrastructure.

5.3 Self-Healing and Responsive PDMS Surfaces

Leveraging the intrinsic chain mobility and elasticity of PDMS, advanced surface designs can recover from minor mechanical damage and dynamically adjust wettability in response to environmental stimuli, supporting the development of smart and adaptive surface systems.

6. Representative Application Scenarios

Microfluidics: Hydrophilically modified PDMS surfaces improve flow stability and analytical accuracy

Electronics: Controlled surface energy and migration behavior enhance encapsulation reliability

Functional Coatings: Modified PDMS silicone fluid formulations from Silico are widely used in anti-fouling, anti-icing, and weather-resistant coating systems

Conclusion: Future Directions in PDMS Silicone Fluid Surface Engineering

PDMS silicone fluid surface treatment technologies are rapidly evolving from simple wettability adjustment toward multifunctional, durable, and intelligent interface engineering. Advances in nanotechnology, surface chemistry, and molecular design are driving PDMS-based materials into increasingly demanding applications across high-end manufacturing, biomedical engineering, and next-generation energy systems.

As a professional silicone materials supplier, Silico® continues to support these innovations by delivering high-performance PDMS silicone fluids tailored for advanced surface modification and functional coating applications.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China