Medical Grade Polydimethylsiloxane | Silico® PDMS

- Blog

- September 15, 2023

- 4:34 pm

Medical grade polydimethylsiloxane (PDMS) is a highly purified, biocompatible silicone material widely used in medical devices, drug delivery systems, and implantable applications. Known for its excellent stability, flexibility, and regulatory compliance, medical PDMS plays a vital role in advancing modern healthcare technology. Silico® offers high-quality PDMS materials that meet international medical standards, providing reliable performance and safety for manufacturers worldwide.

Table of Contents

- 1. What Is Polydimethylsiloxane (PDMS)?

- 2. Key Features and Advantages of Medical Grade PDMS

- 3. Medical vs. Industrial Grade PDMS: What’s the Difference?

- 4. Typical Applications of Medical Grade Polydimethylsiloxane

- 5. Purity and Biocompatibility Requirements

- 6. Regulatory Certifications and Industry Standards

- 7. Processing and Manufacturing Techniques

- 8. How to Choose a Reliable Medical PDMS Supplier

- 9. Conclusion

1. What Is Polydimethylsiloxane (PDMS)?

Polydimethylsiloxane (PDMS) is a silicone-based polymer composed of repeating Si–O–Si backbones with methyl side groups. It is widely known for its excellent thermal stability, chemical inertness, low surface tension, and optical transparency.

Medical grade PDMS refers to highly purified, biocompatible silicone materials that meet strict regulatory standards for use in medical devices, pharmaceutical applications, and implantable medical components.

2. Key Features and Advantages of Medical Grade PDMS

Medical grade polydimethylsiloxane exhibits a unique combination of properties that make it ideal for medical applications:

✅ High Purity – Free from volatile impurities and heavy metals, compliant with pharmacopeia standards.

🧪 Excellent Biocompatibility – Non-cytotoxic, non-irritant, and suitable for long-term contact with human tissue.

🫧 Chemical Inertness – Stable in most solvents and pharmaceutical formulations.

💧 Superior Gas Permeability and Flexibility – Perfect for applications like catheters and membranes.

🔥 High Thermal Stability & Sterilization Resistance – Can withstand autoclaving, gamma sterilization, and EtO treatment.

👉 Silico® PDMS combines these features with tight quality control, ensuring consistent performance across batches.

3. Medical vs. Industrial Grade PDMS: What’s the Difference?

| Parameter | Medical Grade PDMS | Industrial Grade PDMS |

|---|---|---|

| Purity Level | Ultra-high (ppm level impurities) | Standard |

| Biocompatibility | Meets USP Class VI, ISO 10993 | Not certified |

| Regulatory Compliance | FDA, CE, ISO 13485 | Industrial certifications only |

| Application | Medical devices, implants, pharmaceuticals | Lubricants, sealants, release agents |

In short: Medical grade PDMS ensures safety, traceability, and regulatory compliance, which industrial grade products cannot guarantee.

4. Typical Applications of Medical Grade Polydimethylsiloxane

Medical grade PDMS is widely used in various healthcare and life science applications, including:

🫁 Medical Devices: Catheters, syringe plungers, seals, infusion systems

💊 Drug Delivery Systems: Controlled-release membranes, drug coatings

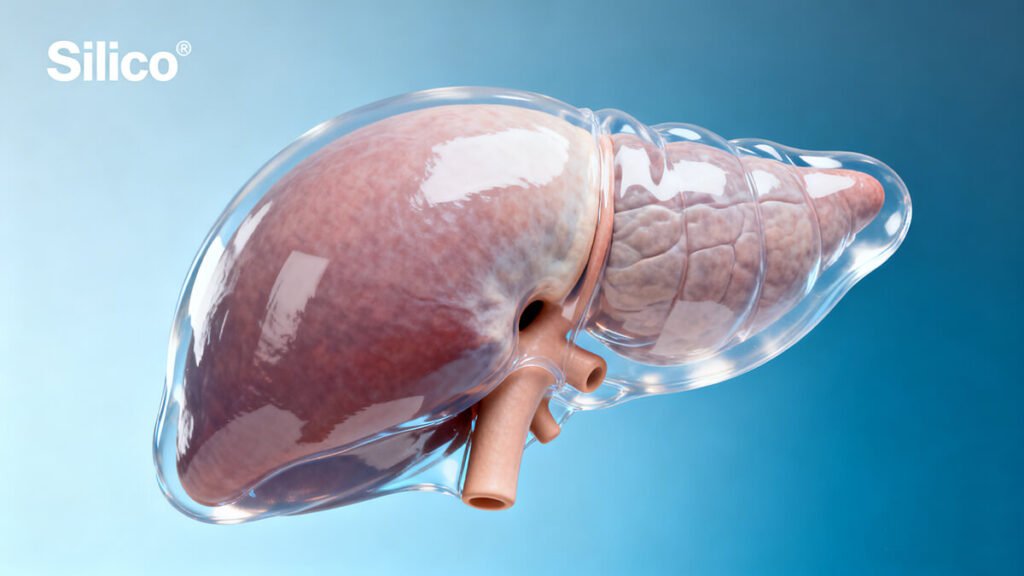

🧬 Implantable Materials: Breast implants, heart valves, reconstructive prostheses

👩⚕️ Aesthetic & Surgical Products: Soft tissue implants, silicone fillers

🧪 Lab-on-a-Chip and Microfluidics: High precision and transparency for bioengineering

👉 Silico® PDMS grades are designed to support both invasive and non-invasive medical applications with high stability and reproducibility.

5. Purity and Biocompatibility Requirements

To ensure patient safety, medical grade PDMS must meet strict purity and biocompatibility criteria:

USP Class VI biological evaluation

ISO 10993 biocompatibility testing

Low extractables and leachables

Free from volatile organics and heavy metals

Validated sterilization compatibility

These standards guarantee that Silico® PDMS can be safely used in sensitive medical and pharmaceutical environments.

6. Regulatory Certifications and Industry Standards

To enter the medical market, medical silicone materials must comply with multiple regulatory frameworks:

🇺🇸 FDA — U.S. Food and Drug Administration medical device compliance

🇪🇺 CE Mark — European regulatory requirements

🌍 ISO 13485 — Quality management systems for medical devices

🧾 REACH / RoHS — Environmental and safety compliance

Silico® PDMS materials are manufactured under strict quality control to help medical device companies meet these regulations smoothly.

7. Processing and Manufacturing Techniques

Medical grade PDMS is highly versatile and can be processed using multiple methods:

Injection molding – for precision components

Extrusion – for tubing and catheter production

Coating and casting – for membranes and drug delivery films

Curing (thermal or UV) – to achieve desired crosslinking and mechanical properties

Silico® PDMS provides excellent consistency and processing stability, helping manufacturers reduce waste and improve efficiency.

8. How to Choose a Reliable Medical PDMS Supplier

When selecting a medical PDMS supplier, consider the following:

✅ Proven compliance with FDA, USP Class VI, ISO 10993

🏭 Consistent batch quality and scalable production capacity

📄 Complete technical documentation (COA, MSDS, TDS)

🌍 Global supply capability with flexible customization options

Silico® offers a full portfolio of medical silicone elastomers and polydimethylsiloxane fluids designed for the healthcare industry, ensuring safety, performance, and global regulatory compliance.

9. Conclusion

Medical grade polydimethylsiloxane (PDMS) has become a cornerstone material in modern healthcare thanks to its purity, biocompatibility, and processing versatility. From life-saving implantable devices to next-generation drug delivery systems, medical silicone plays a critical role in advancing medical technology.

With Silico® Medical Grade PDMS, device manufacturers and pharmaceutical companies can achieve reliable performance, regulatory compliance, and accelerated market entry.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China