How to Improve Polydimethylsiloxane(PDMS) Thermal Stability

- Blog

- October 17, 2022

- 9:46 am

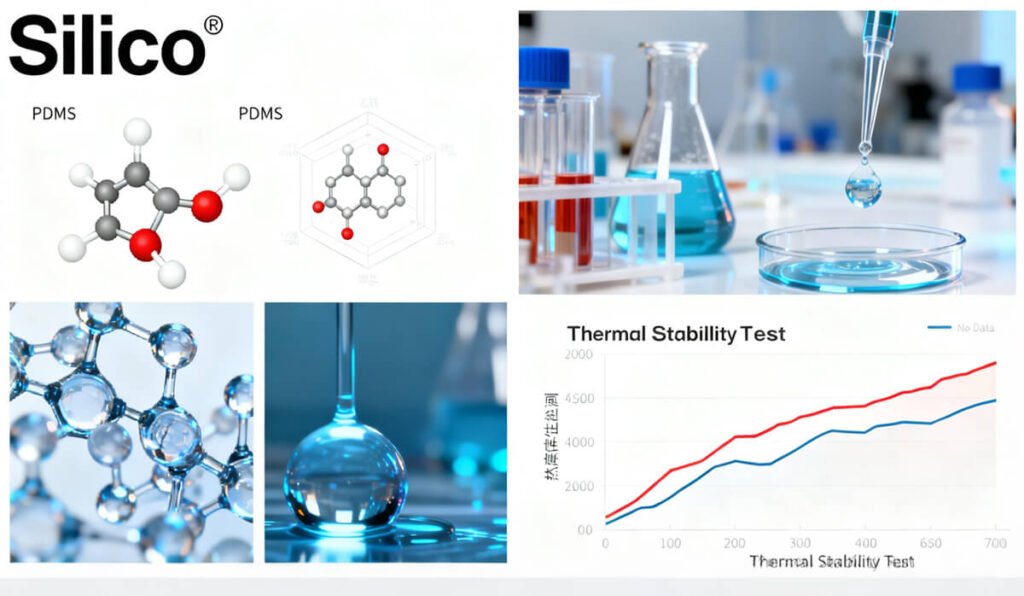

Polydimethylsiloxane (PDMS) naturally exhibits good thermal resistance, but high-temperature or long-term applications require higher levels of stability. Thermal stability can be significantly improved through: (1) chemical modification (phenyl/aryl substitution, POSS, or copolymer design), (2) optimizing crosslink density and chemistry, (3) adding inorganic or nano-fillers (silica, nanoclay, BN, POSS), (4) removing low-molecular-weight species and performing proper post-curing, and (5) using stabilizers, antioxidants, and barrier coatings. Each method has trade-offs involving mechanical properties, processability, and cost. This article—developed with insights from leading silicone suppliers such as Silico®—explains mechanisms, formulation strategies, testing methods, and recommended combinations for different temperature ranges.

Table of Contents

- 1. Introduction: Why Thermal Stability Matters

- 2. How PDMS Degrades Under Heat (Mechanisms)

- 3. Strategy 1: Chemical Modification & Copolymer Design

- 4. Strategy 2: Crosslink Chemistry & Density Optimization

- 5. Strategy 3: Fillers & Nanocomposites

- 6. Strategy 4: Stabilizers, Antioxidants & Additives

- 7. Strategy 5: Processing & Post-Treatment

- 8. Practical Formulation Strategies

- 9. How to Evaluate Thermal Stability Improvements

- 10. Trade-offs, Pitfalls & Troubleshooting

- 11. Quick FAQ

- 12. Final Recommendations

1. Introduction: Why Thermal Stability Matters

Polydimethylsiloxane (PDMS) is widely used due to its flexible Si–O backbone, low surface energy, and excellent chemical inertness. These features already provide decent thermal resistance, but certain industries require far greater long-term thermal and oxidative stability, including:

- aerospace seals

- high-temperature electronic encapsulants

- insulation oils

- microfluidic devices

- specialty coatings and elastomers

Enhancing PDMS thermal stability ensures longer service life, reduced volatilization, improved electrical reliability, and improved retention of mechanical properties.

2. How PDMS Degrades Under Heat (Mechanisms)

- Backbone scission initiated at weak points (impurities, end groups).

- Depolymerization into cyclics and low-molecular-weight siloxanes.

- Oxidative cleavage at elevated temperature in air; accelerated by metal contaminants.

- Catalyst-induced decomposition, influenced by fillers or residues.

3. Strategy 1: Chemical Modification & Copolymer Design

Principles

- Substitute methyl groups with phenyl or aryl groups to increase oxidative resistance and raise Tg.

- Copolymerize PDMS with high-T polysiloxane segments (e.g., polymethylphenylsiloxane).

- Graft or incorporate POSS (polyhedral oligomeric silsesquioxane) units to create thermally robust nano-structured crosslinks.

Practical Guidelines

- Replace 10–30% methyl units with phenyl groups for moderate improvement.

- POSS improves char yield and shifts degradation onset upward.

- Maintain a balance between stiffness and flexibility.

4. Strategy 2: Crosslink Chemistry & Density Optimization

Why it Works

Higher crosslink density reduces chain mobility, suppresses volatilization of oligomers, and stabilizes the polymer network.

Recommended Approaches

- Use multi-functional silanes or reactive low-molecular-weight siloxane crosslinkers.

- Prefer addition-cure (Pt-catalyzed) or peroxide-cure systems with stable C–C or Si–O crosslinks.

- Minimize catalytic residues (Pt, Sn), which may accelerate thermal degradation over time.

Tips

- Remove sol/low-MW species.

- Avoid excessive crosslink density to prevent brittleness.

5. Strategy 3: Fillers & Nanocomposites

Most Effective Fillers

- Fumed silica (surface treated): enhances mechanical strength and thermal stability.

- Nanoclay / montmorillonite: creates a diffusion barrier that slows volatilization and oxidation.

- Boron nitride (BN), alumina, ceramic whiskers: improve heat dissipation and reduce hotspots.

POSS: acts as both a filler and structural stabilizer.

Critical Note

The polymer–filler interface is essential. Poorly dispersed or metal-contaminated fillers may accelerate degradation.

Silico® PDMS grades with optimized silica dispersion often exhibit better thermal aging behavior.

6. Strategy 4: Stabilizers, Antioxidants & Additives

What Works in PDMS

- Silicone-compatible phosphites/phosphonates and hindered phenolic antioxidants.

- Metal deactivators to neutralize catalytic trace metals.

- Ceramic-forming additives for extreme environments.

Important Tips

Most conventional polymer antioxidants are developed for hydrocarbons—compatibility with PDMS must be verified through accelerated aging tests.

7. Strategy 5: Processing & Post-Treatment

Key Processing Controls

- Remove low-molecular-weight components via solvent extraction or controlled thermal/vacuum annealing.

- Post-cure at elevated temperature to complete crosslinking and reduce volatile species.

- Use inert atmosphere (nitrogen/argon) during curing for oxidation-critical applications.

For device applications:

Vacuum bake components at a temperature slightly below the operating temperature to remove volatiles and stabilize performance.

8. Practical Formulation Strategies

Moderate Improvement (≤150–200°C)

- Treated fumed silica

- Multifunctional crosslinker

- Thorough post-cure

High-Temperature Applications (200–300°C)

- 10–30% phenyl-modified PDMS

- POSS or nanoclay incorporation

- Sol removal + antioxidants

Extreme Conditions (>300°C)

- High-phenyl or aromatic polysiloxane copolymers

- Ceramic fillers (BN, alumina, whiskers)

- Ceramic/ablative coating layers

POSS-rich hybrid architectures

9. How to Evaluate Thermal Stability Improvements

- TGA: onset temperature (Tonset), Tmax, char yield.

- DSC / DMA: Tg, storage modulus, thermal transitions.

- Isothermal aging: mass loss over time at the intended service temperature.

- FTIR / GC-MS: identify volatile degradation products.

Kinetic analysis (Arrhenius or Kissinger): calculate activation energy for decomposition.

10. Trade-offs, Pitfalls & Troubleshooting

- Phenyl substitution increases stiffness. Balance flexibility vs. stability.

- High filler loading increases viscosity. May require equipment adjustments.

- Some fillers catalyze degradation. Use high-purity, surface-treated fillers.

Catalyst residues may accelerate breakdown—remove or passivate them.

11. Quick FAQ

Q: Do carbon nanotubes always improve thermal stability?

A: Not always. CNTs increase thermal conductivity but may accelerate degradation depending on impurities and surface chemistry.

Q: Is post-curing necessary?

A: In most systems, yes—post-curing removes volatiles and completes crosslinking, raising the degradation onset temperature.

Q: What is the fastest improvement with the lowest risk?

A: Removing low-MW species + adding treated fumed silica typically delivers consistent benefits with minimal drawbacks.

12. Final Recommendations

- Define the thermal environment (air vs. inert).

- Always perform post-curing and oligomer removal.

- Combine phenyl modification, fumed silica, and stabilizers for balanced improvement.

- Use ceramic fillers or POSS for extreme conditions.

- Validate through TGA, DMA, and isothermal aging tests.

For advanced PDMS systems, Silico® high-performance silicone fluids and copolymers offer improved thermal resistance and optimized filler-matrix interfaces, making them suitable for demanding high-temperature applications.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China