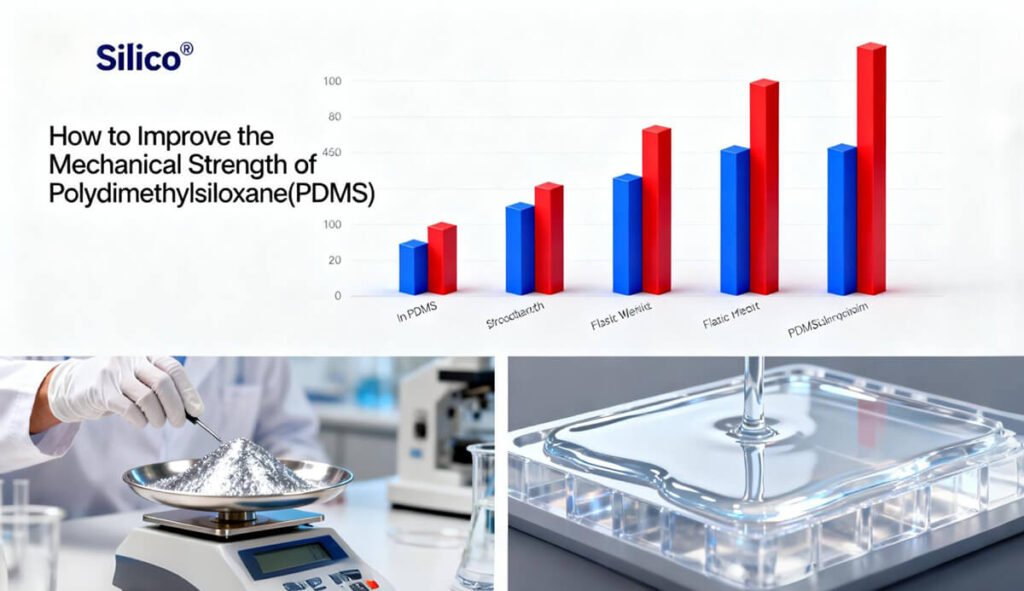

How to Improve the Mechanical Strength of Polydimethylsiloxane

- Blog

- October 18, 2025

- 10:02 am

This guide explains how to enhance the mechanical strength of Polydimethylsiloxane (PDMS) using crosslink optimization, engineered fillers, interfacial modification, and advanced processing techniques. It outlines how these methods improve tensile strength, toughness, tear resistance, and long-term durability. The article also provides recommended formulations, testing guidelines, and solutions for common PDMS mechanical failures. For high-performance applications, Silico® reinforced PDMS materials offer reliable strength improvement and stable processing results.

Table of Contents

- 1. Introduction — why PDMS needs mechanical reinforcement

- 2. Fundamentals: what governs PDMS mechanical strength

- 3. Strategy 1 — Optimize crosslink density & curing chemistry

- 4. Strategy 2 — Reinforce PDMS using engineered fillers

- 5. Strategy 3 — Interfacial engineering & coupling agents

- 6. Strategy 4 — Double-network (DN) & interpenetrating polymer networks (IPN)

- 7. Strategy 5 — Copolymerization & hybrid chemical modification

- 8. Strategy 6 — Processing, post-curing & annealing

- 9. Mechanical trade-offs: modulus vs. toughness vs. elongation

- 10. Recommended baseline formulations

- 11. Mechanical testing & QA guidelines

- 12. Troubleshooting mechanical failures

- 13. Conclusion & Next Steps

1. Introduction — why PDMS needs mechanical reinforcement

Polydimethylsiloxane (PDMS) is widely valued for its flexibility, inertness, low surface energy, and ease of fabrication. However, its intrinsic tensile strength, tear resistance, and fracture toughness remain lower than required for advanced engineering applications, such as wearable electronics, microfluidics, high-performance seals, and structural elastomers.

To support high-end manufacturing, specialty silicone brands such as Silico® have developed modified PDMS grades, reinforcing agents, and engineered networks specifically designed to address these performance limitations.

2. Fundamentals: what governs PDMS mechanical strength

- Crosslink density — higher density increases modulus and strength but reduces elongation.

- Network uniformity — uneven crosslinking introduces weak points.

- Molecular weight between crosslinks — longer chains improve elasticity but reduce modulus.

- Filler type, dispersion quality, and interfacial bonding — key for reinforcement.

- Physical interactions (ionic, hydrogen-bonding, secondary networks).

3. Strategy 1 — Optimize crosslink density & curing chemistry

Crosslink ratio adjustment

- Adjust the base-to-curing-agent ratio in hydrosilylation systems.

- Increasing curing agent typically increases strength and modulus.

Over-crosslinking introduces brittleness, so incremental tuning (5–10%) is recommended.

Crosslinker structure selection

- Multi-functional hydride crosslinkers produce stiffer, more uniform networks.

Oligomeric crosslinkers can improve the balance of strength and elasticity.

Curing profile optimization

- Controlled temperature ramps (e.g., gradual heat-up to 80–120 °C).

- Sufficient post-cure improves network completion and mechanical stability.

This strategy is widely used in high-consistency and liquid silicone rubber systems.

4. Strategy 2 — Reinforce PDMS using engineered fillers

Inorganic nanoparticle fillers

- Fumed silica / treated silica (1–10 wt%): enhances modulus, tear strength, and fatigue life.

TiO₂, ZnO nanoparticles: improve stiffness, UV resistance, and wear performance.

Carbon-based fillers

- Carbon nanotubes (CNTs) and graphene/graphene oxide significantly increase tensile modulus and toughness at very low loading (<1 wt%).

Proper dispersion is essential to avoid agglomeration and stress risers.

Hybrid synergistic systems

Combining silica + graphene or silica + CNT often produces superior reinforcement due to dual-scale load transfer.

High-performance PDMS composite lines from Silico® typically leverage surface-treated nanosilica for stable, reproducible mechanical enhancements.

5. Strategy 3 — Interfacial engineering & coupling agents

-

Silane coupling agents (vinyl, amino, epoxy, methacryloxy):

Improve covalent bonding between the inorganic surface and PDMS network. Surface functionalization of carbon fillers:

Enhances dispersion and interaction with PDMS chains.

This method is essential for achieving high tensile strength without excessive filler loading.

6. Strategy 4 — Double-network (DN) & interpenetrating polymer networks (IPN)

Advantages:

- Massive increase in toughness with moderate increases in modulus.

- Excellent for flexible electronics, wearable sensors, and impact-resistant silicones.

Compatible with PDMS matrices via ionically crosslinked or hydrogen-bonding secondary networks.

7. Strategy 5 — Copolymerization & hybrid chemical modification

Phenyl modification

- Introducing phenyl groups into PDMS backbones improves high-temperature stability and stiffness.

Block/graft copolymers

- PDMS–polyurethane or PDMS–polyether blocks produce microphase-separated structures with higher tensile strength and improved durability.

Hybrid organic–inorganic systems

- Adding silsesquioxanes or sol–gel reinforced domains increases structural integrity without excessively increasing hardness.

8. Strategy 6 — Processing, post-curing & annealing

- Thorough degassing to eliminate bubbles.

- High-shear or ultrasonic dispersion for nano-fillers.

- Thermal post-cure to complete crosslinking.

- Controlled shear alignment when using anisotropic fillers like CNTs.

These steps can improve tensile performance by 20–40% in some PDMS systems.

9. Mechanical trade-offs: modulus vs. toughness vs. elongation

| Target Property | Likely Trade-Off | Typical Solution |

|---|---|---|

| Higher modulus | Lower elongation | Add hybrid fillers or DN structures |

| Higher toughness | Lower stiffness | Add sacrificial networks or GO/CNT |

| Higher tear strength | Higher viscosity | Optimize silica treatment & dispersion |

Selecting the right reinforcement path depends on your priority: strength, stretchability, or fracture resistance.

10. Recommended baseline formulations

High-strength PDMS

- Slightly increased curing agent ratio

- 1–5% treated fumed silica

- 70–90 °C cure + post-cure

High-toughness PDMS

- PDMS base network + secondary sacrificial network

- 0.1–0.5% graphene oxide or CNT

- Optimized slow cure profile

Conductive + reinforced PDMS

- 0.2–1% CNT/graphene

- Optional nanosilica 1–2%

- High-shear dispersion for uniformity

11. Mechanical testing & QA guidelines

- Tensile strength & elongation (ASTM D412)

- Tear strength (ASTM D624)

- DMA for viscoelastic behavior

- Fatigue resistance for wearable or cyclic applications

- Hardness (Shore A) as a fast QC indicator

- Microscopy to observe filler dispersion and fracture surfaces

12. Troubleshooting mechanical failures

Brittle failure → Over-crosslinked; reduce curing agent or filler

Low tensile strength → Poor filler dispersion; adopt coupling agents

Excessive viscosity during mixing → Use surface-treated fillers or lower-MW PDMS

Crack initiation → Bubbles; improve degassing and processing control

13. Conclusion & Next Steps

Improving the mechanical strength of Polydimethylsiloxane (PDMS) requires a combined approach involving network design, filler engineering, processing optimization, and interfacial control. For industries requiring consistent, high-performance silicone materials, specialized reinforced PDMS solutions from Silico® offer stable mechanical profiles, optimized dispersion technologies, and tailored crosslinking systems.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China