Enhancing PDMS Dielectric Strength in Insulating Oils

- Blog

- December 6, 2022

- 4:39 pm

In high-voltage systems such as transformers, switchgear, and capacitors, liquid insulating oils play a critical dual role — providing electrical insulation and transferring heat.

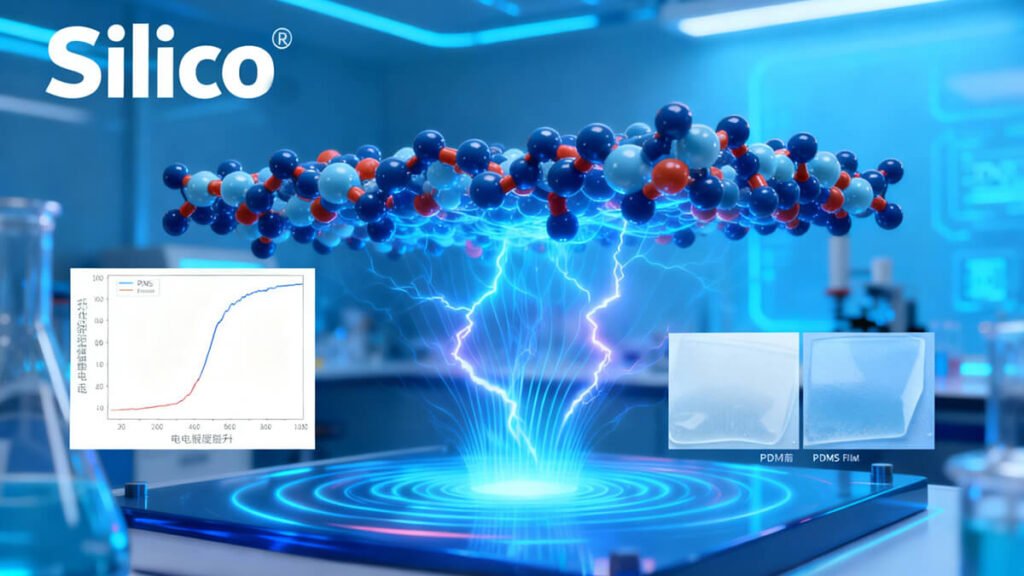

Traditional mineral oils face limitations in oxidation stability, moisture tolerance, and fire safety. Polydimethylsiloxane (PDMS), as a silicone-based insulating fluid, offers a superior alternative with high thermal stability, chemical inertness, low dielectric loss, and broad operational temperature range.

For example, a 50 cSt PDMS silicone oil demonstrates breakdown voltages up to 50 kV, highlighting its potential as a next-generation dielectric medium.

Table of Contents

- 1. Understanding the Fundamentals

- 2. Benefits and Challenges of PDMS-Based Insulating Oils

- 3. Key Factors Affecting Dielectric Strength

- 4. Proven Methods to Enhance Dielectric Strength

- 5. Research Insights and Industrial Applications

- 6. Recommendations for Silico® PDMS Insulating Oils

- 7. Conclusion and Future Trends

1. Understanding the Fundamentals

What Is PDMS (Polydimethylsiloxane)?

- High electrical resistivity

- Low dielectric loss

- Hydrophobic and oxidation-resistant properties

Role of Liquid Electrical Insulating Oils

- Prevent arcing and corona discharge between conductors

- Cool components such as coils and cores

- Suppress partial discharges and delay dielectric breakdown

Definition of Dielectric Strength and Its Importance

Dielectric strength (or breakdown voltage) represents the maximum electric field a liquid can withstand before electrical failure. It directly determines the safety margin and reliability of high-voltage equipment.

2. Benefits and Challenges of PDMS-Based Insulating Oils

Advantages

- Superior thermal stability and oxidation resistance

- High breakdown voltage (~50 kV) and low dielectric loss (tan δ < 0.0001)>

- High flash point (~300 °C) for improved fire safety

- Eco-friendly, non-toxic, and recyclable

Challenges

- Impurities, microbubbles, and water contamination reduce breakdown strength

- Poor dispersion or filler instability leads to localized discharge

- Interface degradation and moisture ingress accelerate aging

3. Key Factors Affecting Dielectric Strength

| Factor | Impact | Optimization Strategy |

|---|---|---|

| Purity | Impurities cause discharge initiation | Use ultra-pure PDMS base fluids |

| Bubbles / Voids | Create localized field enhancements | Apply vacuum degassing & slow filling |

| Moisture | Reduces resistivity and breakdown voltage | Maintain ≤ 50 ppm water content |

| Filler Dispersion | Agglomeration causes field distortion | Use silane-treated nano-fillers |

| Temperature & Aging | Promotes degradation and gas formation | Monitor viscosity & electrical loss |

| Electrode Geometry | Influences local field stress | Employ smooth electrodes & standardized test setups |

4. Proven Methods to Enhance Dielectric Strength

High-Purity PDMS + Vacuum Degassing

Incorporating Nano-Fillers

Interface Modification

Process Optimization

Aging Control & Monitoring

Establish oil testing schedules (breakdown voltage, resistivity, tan δ, moisture). Replace or regenerate oils based on predictive condition analysis.

5. Research Insights and Industrial Applications

PDMS in Transformer Applications

- Breakdown voltage ≈ 50 kV

- Resistivity ≈ 1×10¹⁴ Ω·cm

- Moisture < 50 ppm

- Flash point ≈ 300 °C

Nanocomposite Innovation

6. Recommendations for Silico® PDMS Insulating Oils

Product Specification Targets

- Base Fluid: PDMS (20–50 cSt, ≥ 99.9% purity)

- Water Content: ≤ 50 ppm

- Breakdown Voltage: ≥ 50 kV (ASTM D877)

- Volume Resistivity: ≥ 1×10¹⁴ Ω·cm

- Flash Point: ≥ 300 °C

- Dielectric Loss (tan δ): ≤ 0.0001

Production & Quality Control

- Vacuum dehydration and degassing under inert gas

- Inline filtration (< 1 µm)

- Batch certification with MSDS/TDS download available

- Traceability and lifecycle data tracking

7. Conclusion and Future Trends

As electrical systems move toward higher voltages, compact designs, and greener operation, PDMS-based silicone insulating oils will play a pivotal role.

Through advanced purification, nano-modification, and optimized system design, Silico® can pioneer the next generation of high-dielectric-strength insulating oils — delivering exceptional safety, performance, and environmental value.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China