How to Select the Right Amino Silicone Oil Grade

- Blog

- October 13, 2020

- 3:07 pm

Choosing the right amino silicone oil grade is essential for achieving optimal softness, smoothness, and durability in textile finishing, personal care, and industrial applications. This comprehensive guide explores key factors such as amine value, viscosity, compatibility, and active content, helping formulators and manufacturers make data-driven decisions. With a focus on performance efficiency and surface modification technology, Silico® Amino Silicone Oils provide tailored solutions that enhance fabric handle, coating adhesion, and long-term stability. Whether for textile finishing, hair conditioning, or industrial emulsions, Silico® delivers consistent quality and proven reliability.

Table of Contents

- 1. Introduction — Why Grade Selection Matters

- 2. What Is Amino Silicone Oil?

- 3. Four Core Selection Parameters

- 4. Matching Grades to Fiber and End-Use

- 5. Emulsion Type and Processing

- 6. Performance Tradeoffs and Special Requirements

- 7. Quality Control — Key Tests and Specifications

- 8. Typical Formulation and Application Methods

- 9. Troubleshooting Common Issues

- 10. Selection Checklist and Case Example

- 11. Conclusion — Partner with Silico®

1. Introduction — Why Grade Selection Matters

Selecting the right amino silicone oil grade is crucial for ensuring consistent fabric hand-feel, long-term durability, and production stability. The wrong grade can lead to issues such as yellowing, poor hand, or silicone spotting.

Silico® Amino Silicone Oils are engineered with precise control over molecular weight, amine value, and functionality, ensuring superior fabric compatibility and process efficiency. Choosing the right grade means aligning chemical characteristics with substrate type, finishing process, and performance expectations.

2. What Is Amino Silicone Oil?

Amino silicone oils are organosilicon polymers with amino-functional side groups that provide affinity toward natural and synthetic fibers. These functional groups improve softness, flexibility, and durability compared to non-functional silicone fluids.

They can be supplied as neat fluids or pre-emulsified concentrates, depending on application needs. Silico® offers both formats with customized molecular structures for textile, leather, and industrial finishing applications.

3. Four Core Selection Parameters

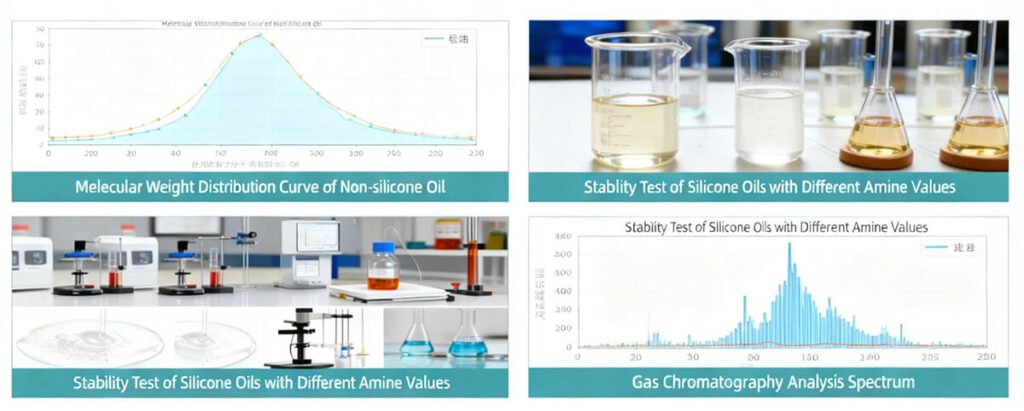

3.1 Amine Value (Amine Content)

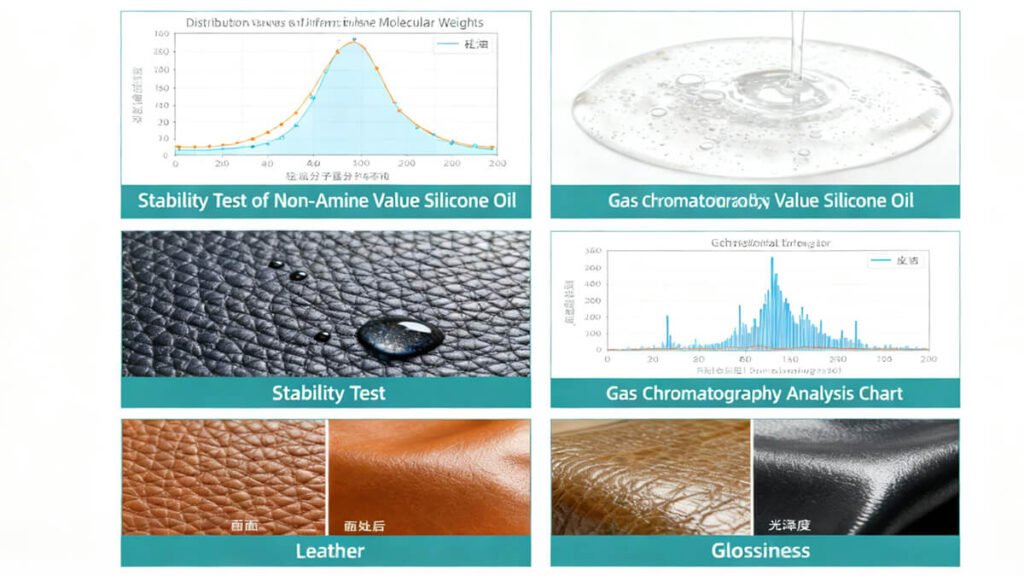

- Definition: Amine value measures the amount of reactive amino groups (mg KOH/g).

- Impact: Higher amine value improves bonding strength and durability, but may slightly increase yellowing tendency.

- Selection Tip: For light-colored or white fabrics, use low-yellowing Silico® Amino Silicone Oils with controlled amine content to maintain brightness and hand quality.

3.2 Base Fluid Viscosity

- Low viscosity (<100 cSt): Ideal for light fabrics requiring quick wetting.

- Medium viscosity (100–1000 cSt): Balanced softness and durability.

-

High viscosity (>1000 cSt): Excellent fullness and hand for heavy fabrics or upholstery applications.

Silico® precisely tunes viscosity through polymer chain design, ensuring consistent emulsion behavior and uniform softening effect.

3.3 Functional Structure

- Monoamine: Provides slick and smooth hand feel.

- Diamine: Delivers improved softness and fabric body.

- Trifunctional / crosslinkable: Enhances elasticity and crease recovery for high-end finishing.

3.4 Hydrophilicity and Co-Functionality

Hydrophilic performance can be adjusted by incorporating polyether segments or blocked amino groups. This allows Silico® Amino Silicone Oils to provide both moisture management and soft touch for performance textiles.

4. Matching Grades to Fiber and End-Use

| Fiber Type | Recommended Amine Value | Suggested Silico® Grade Characteristics |

|---|---|---|

| Cotton / Viscose | Medium (~0.6) | Durable softening, low yellowing |

| Polyester / Nylon | Low (~0.3) | Smooth touch, non-greasy feel |

| Silk / Wool | Low viscosity | Glossy and delicate hand |

| Upholstery / Denim | High viscosity | Rich, bulky, and long-lasting hand |

Tip: For white or pastel fabrics, select Silico® low-yellowing amino silicone oils tested for thermal and alkaline stability.

5. Emulsion Type and Processing

- Micro vs. Macro Emulsion: Microemulsions provide finer droplets, more uniform softening, and lower risk of oil spots.

- Emulsifier Type: Nonionic systems ensure better compatibility with dyes and auxiliaries.

- Droplet Size: Smaller droplets enhance fabric uniformity; controlled by Silico®’s proprietary emulsion process.

- pH & Hardness: Test emulsion stability under actual process conditions; hardness >100 ppm may destabilize poor formulations.

6. Performance Tradeoffs and Special Requirements

- Low-Yellowing Grades: Choose Silico® amino silicone oils formulated with low-chromophore backbones and minimal volatile siloxanes.

- Durability: Higher amine value = better bonding, but balance with yellowing control.

- Hydrophilic Finishes: For sportswear or comfort fabrics, use polyether-modified variants to maintain moisture transport.

7. Quality Control — Key Tests and Specifications

Recommended Supplier Specifications

| Parameter | Typical Range | Notes |

|---|---|---|

| Amine Value | 0.3–0.8 mg KOH/g | Defines reactivity |

| Viscosity | 100–3000 cSt @25°C | Affects softness and emulsion stability |

| Solid Content (emulsion) | 25–35% | Microemulsion preferred |

| Droplet Size (D50) | <0.3 µm | Prevents oil spotting |

| Storage Stability | ≥12 months | Room temperature |

In-House Quality Testing

- Fabric whiteness (ΔE) after curing and aging

- Softness and elasticity (panel or Kawabata test)

- Wash durability and sweat resistance

- Moisture vapor transmission for hydrophilic grades

- Emulsion stability under varying water hardness

8. Typical Formulation and Application Methods

Pad-Dry-Cure

- Amino silicone emulsion (solid): 1–6% owf

- Crosslinker (if applicable): follow supplier guide

- Nonionic co-softener: 0.5–2% owf

- Dry: 100–130°C → Cure: 150–170°C (brief time)

Recommended Supplier Specifications

- Amino silicone emulsion: 0.5–2% owf

- Gentle agitation (30–60°C) to minimize spots

- Neutral to slightly acidic bath for better adsorption

Recommended Supplier Specifications

Use high-viscosity or crosslinkable Silico® grades for durable softness and abrasion resistance.

9. Troubleshooting Common Issues

| Problem | Cause | Recommended Solution |

|---|---|---|

| Silicone spots | Droplet size too large | Use Silico® microemulsion grades |

| Fabric yellowing | High amine value or heat exposure | Switch to low-yellowing grade, reduce curing temp |

| Low durability | Incomplete crosslinking | Increase amine value or adjust curing conditions |

| Poor compatibility | Ionic mismatch | Choose nonionic co-surfactants or Silico® stable emulsions |

10. Selection Checklist and Case Example

- Fabric type and color

- Desired hand (soft vs smooth)

- Durability level (wash cycles)

- Application method and temperature range

- Key supplier specs verified (amine value, viscosity, emulsion type)

Example:

For cotton terry towels, select a medium-viscosity Silico® amino silicone oil (amine value ~0.6) with microemulsion stability to deliver a plush and durable hand without yellowing after repeated washing.

11. Conclusion — Partner with Silico®

Selecting the right amino silicone oil requires understanding both chemical structure and processing requirements. By choosing a scientifically balanced grade—optimized for amine value, viscosity, and emulsion stability—you can achieve superior softness, whiteness retention, and wash durability.

Silico® provides a complete range of amino silicone oils and customized technical support for textile and leather formulators. Contact our R&D team for grade recommendations, application data, and sample testing support tailored to your specific finishing line.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China