How to Choose Hydroxy Silicone Oil by Viscosity & OH Value

- Blog

- September 15, 2022

- 9:07 am

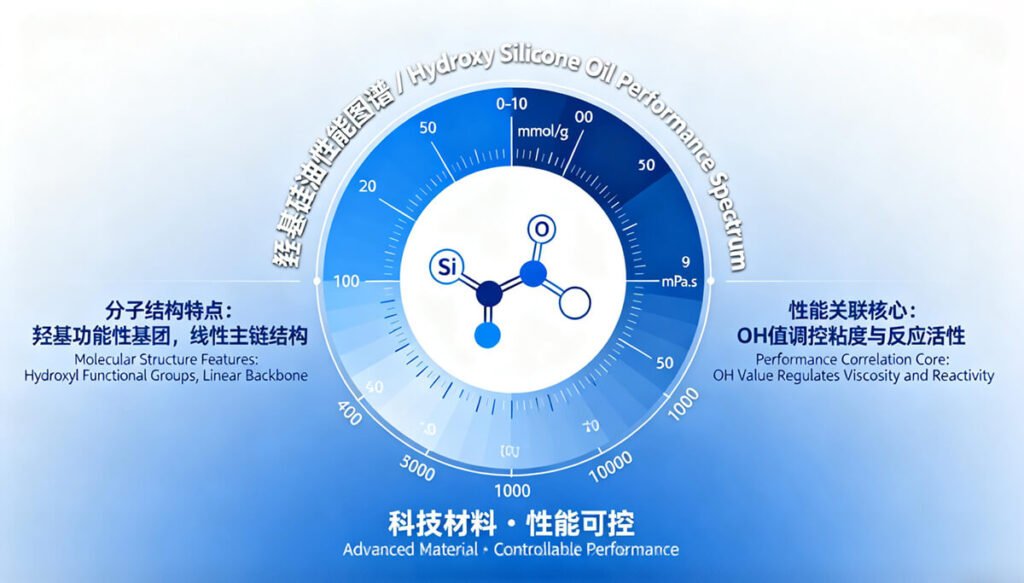

Selecting the correct hydroxy silicone oil relies primarily on evaluating viscosity (molecular weight, flow behavior, film formation) and OH value (reactivity, compatibility, crosslinking potential). These two parameters govern wetting, durability, emulsification stability, and chemical bonding efficiency. High-performance manufacturers such as Silico® provide precise viscosity/OH-value combinations tailored for coatings, elastomers, release systems and advanced surface modification applications.

A smart selection balances mobility (viscosity) with reactivity (OH value), ensuring both processing efficiency and long-term performance.

Table of Contents

- 1. Why viscosity and OH value matter — the fundamentals

- 2. How viscosity and OH value interact (chemistry → performance)

- 3. Practical selection rules by application

- 4. Emulsion & processing considerations

- 5. Application Guide by Industry

- 6. Typical starting formulations

- 7. Troubleshooting common failures & solutions

- 8. Selection checklist & case example

- 9. Conclusion & next steps

1. Why viscosity and OH value matter — the fundamentals

Viscosity (cSt @ 25°C)

- Directly correlated with polymer chain length and molecular weight.

- Controls spreading, penetration, film uniformity, and emulsification.

- Lower viscosity = higher mobility + easier high-shear emulsification.

- Higher viscosity = stronger film formation + improved durability.

OH Value (mg KOH/g or %OH)

- Indicates the concentration of terminal hydroxyl groups.

- Determines chemical reactivity with crosslinkers, resins, isocyanates, alkoxy silanes, or metal alkoxides.

- Higher OH → stronger interfacial bonding and higher crosslink density.

- Lower OH → more inert behavior, stronger hydrophobicity, better lubrication.

Both parameters should be evaluated jointly—changing viscosity affects the effective exposure and accessibility of OH groups during reaction or bonding.

2. How viscosity and OH value interact (chemistry → performance)

Reactivity vs. Mobility

- High OH + low viscosity: fast surface wetting, rapid coupling, ideal for primers and reactive coatings.

- High OH + high viscosity: strong reactivity but slower flow, suitable for sealants, thick coatings, and structural elastomer blends.

Crosslinking & mechanical behavior

- High OH increases potential crosslink points.

- Proper viscosity ensures OH groups can diffuse and participate effectively in cure reactions.

- Balanced grades deliver optimum elasticity, modulus, and long-term stability.

Emulsion behavior

- High-viscosity oils require higher shear to form stable small droplets.

- High-OH oils exhibit slightly higher polarity and require optimized emulsifier systems.

- Hydroxy silicone oils with controlled viscosity/OH ratios (such as mid-range Silico® grades) typically produce better microemulsions and more uniform film formation.

3. Practical selection rules by application

A. Silicone rubber compounding (RTV / HTV / LSR)

- Choose medium–high OH value for efficient coupling.

- Viscosity should align with the target compound rheology (100–10,000 cSt).

- Higher OH improves reinforcement and bonding between filler and polymer matrix.

B. Coatings & resin modification

- Select low-to-medium viscosity oils with moderate OH to ensure surface migration, slip performance, and controlled grafting onto resin systems.

- Balances leveling, scratch resistance, gloss control, and coating smoothness.

C. Mold release & paper/adhesive release coatings

- For physical slip: choose low OH + low viscosity.

- For durable chemical anchoring: choose medium-to-high OH combined with viscosities that support stable film formation.

D. Lubricants & mechanical systems

- Prefer low-OH grades for pure hydrophobic lubrication.

- Adjust viscosity to match operating temperature and load requirements.

E. Waterborne emulsions (cements, coatings, textiles)

- OH and viscosity must be compatible with emulsifier, pH, water hardness, and shear conditions.

- For stable microemulsions: moderate viscosity + controlled OH value yields optimal droplet size distribution.

4. Emulsion & processing considerations

- Droplet size: Smaller droplets reduce spotting and improve performance consistency.

- Emulsifier selection: OH-containing silicones often favor mixed nonionic systems.

- Water hardness: Ca²⁺/Mg²⁺ may destabilize emulsions—always test with production water.

- Thermal stability: Hydroxyl groups may initiate slow condensation; controlled storage conditions are required.

5. Key specifications and test methods

Core parameters

- Viscosity (cSt @ 25°C)

- OH value (mg KOH/g or %OH)

- Polydispersity Index (PDI)

- Volatile low-MW siloxane content

- Emulsion solids, droplet size (if applicable)

Recommended lab tests

- Contact angle & surface energy

- Cure kinetics (DSC/rheometry)

- Adhesion & mechanical strength

- Accelerated aging (thermal, UV, chemical)

These tests help predict real-world process compatibility and long-term performance.

6. Typical starting formulations

A. Resin modification

- Hydroxy silicone oil: 0.5–5.0 wt%

- Moderate OH, medium viscosity recommended for balanced flow + grafting.

B. Silicone elastomer modification

- Hydroxy silicone oil: 1–10 phr

- Match OH to crosslinker stoichiometry to avoid over- or under-cure.

C. Waterborne release or cement additives

- Hydroxy silicone emulsion: 0.1–1.0%

- Optimize contact angle, anti-stick behavior, and visual performance.

7. Troubleshooting common failures & solutions

Issue: Emulsion instability or phase separation

Fix: Reduce viscosity, apply high-shear emulsification, adjust emulsifier blend.

Issue: Premature viscosity increase or unexpected curing

Fix: Reduce OH value, avoid catalytic impurities, optimize storage conditions.

Issue: Poor bonding or insufficient durability

Fix: Increase OH content, add silane crosslinkers, or raise temperature during cure.

Issue: Reduced lubricity in mechanical applications

Fix: Blend with low-OH PDMS to restore hydrophobic lubrication.

8. Selection checklist & case example

Checklist

- Required durability

- Wetting or film-forming needs

- Viscosity compatibility

- Required reactivity (OH value)

- Emulsion or neat-fluid processing

- Water hardness, pH, temperature limits

Case example — Release coating for tape liners

- Requirement: Excellent release, long-term anti-adhesion, minimal migration.

Recommended grade: Medium-viscosity, moderate-OH hydroxy silicone oil (Silico® R-series) to chemically anchor within binder systems while delivering controlled slip.

9. Conclusion & next steps

Selecting hydroxy silicone oil by viscosity and OH value is the most effective way to engineer predictable performance in coatings, elastomers, lubricants, and release agents. Manufacturers like Silico® provide optimized molecular structures, controlled OH functionality, and high purity levels that help achieve superior performance in both solvent-based and waterborne systems.

For best results, shortlist 2–3 viscosity/OH combinations and validate them through application-specific testing under real process conditions. Proper selection leads to improved stability, cleaner release, stronger bonding, smoother surfaces, and long-term reliability.

Popular Recommendations

Get a Catalog & Best Price

- Quick and helpful reply within 24 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

TRENDING

Silico® ORGANOSILICON

- Address: Daiyue Industrial Area, Taian, Shandong, China