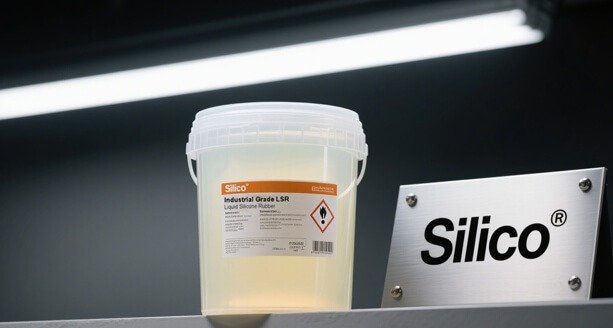

Medical Grade LSR Silicone Rubber

Silico® Medical Grade LSR is a high-purity, platinum-cured silicone for medical molding. It offers biocompatibility, sterilization resistance, and stability for drug delivery, surgical, and diagnostic devices.

Product Overview

Silico® Medical Grade LSR (Liquid Silicone Rubber) is a high-purity, platinum-cured, two-part silicone elastomer engineered for precision liquid injection molding (LIM) in medical and healthcare applications. Designed for direct or indirect human body contact, Silico® Medical LSR combines excellent biocompatibility, sterilization resistance, and dimensional stability, making it ideal for critical components used in diagnostics, drug delivery, respiratory, and surgical devices.

Manufactured under strict quality control in clean processing environments, Silico® Medical LSR ensures reliable performance, low extractables, and full compliance with international medical safety standards.

Key Technical Specifications

| Property | Typical Range |

|---|---|

| Mixing Ratio (A:B) | 1:1 |

| Viscosity (mixed, @25 °C) | 1,000–5,000 mPa·s |

| Shore A Hardness | 20–70 |

| Tensile Strength | 8–10 MPa |

| Elongation at Break | 400–750 % |

| Tear Strength | 25–45 kN/m |

| Compression Set (22h/175 °C) | ≤25% |

| Thermal Service Range | –50 °C to +200 °C (short-term to 250 °C) |

| Sterilization Compatibility | Autoclave, Gamma, ETO, E-Beam |

- Note: Technical properties may vary by formulation. Custom grades are available for specific medical applications.

Key Certifications & Regulatory Compliance

Silico® Medical LSR complies with global medical and food-contact regulations, including:

USP Class VI and ISO 10993 (parts 5, 10, 11)

FDA 21 CFR 177.2600 – suitable for repeated-use food-contact applications

REACH, RoHS, BPA-free, halogen-free

Compatible with autoclave, gamma, e-beam, and EtO sterilization methods

Manufactured under ISO 9001 and ISO 13485 quality systems (upon request)

These certifications ensure Silico® LSR is safe for use in both short-term and prolonged medical contact scenarios.

Typical Applications

Silico® Medical Grade LSR is widely used in:

Surgical & diagnostic devices: seals, valves, membranes, diaphragms

Drug delivery systems: syringe tips, vial stoppers, pump seals

Respiratory & anesthesia equipment: masks, connectors, ventilator valves

Catheters and tubing: feeding tubes, wound drains, closure caps

Wearable healthcare components: soft touch interfaces, skin-contact patches

Processing Information

Silico® LSR is optimized for high-volume, flash-free liquid injection molding:

Mixing: 1:1 ratio with static or dynamic mixers

Injection unit cooling: 15–25 °C to prevent premature curing

Mold temperature: 150–180 °C

Cycle time: 10–60 seconds depending on part thickness

No post-cure required for most medical-grade parts (unless specified)

Advanced flow behavior ensures precise molding of thin-walled and micro-scale components, with excellent demolding performance.

Key Benefits of Silico® Medical LSR

✔ Platinum-cured system: no by-products, ultra-low volatility

✔ Medical-grade purity: non-cytotoxic, non-sensitizing, non-irritating

✔ High flexibility and elongation: ideal for dynamic and skin-contact parts

✔ Superior sterilization resistance: supports multiple reprocessing cycles

✔ Consistent quality: batch-to-batch repeatability, traceable production

✔ Customizable: color matching, durometer tuning, bonding properties available

Packaging Options

Available in:

▪ 20 kg pails (A/B)

▪ 200 kg drums

▪ 1000 kg IBCs for bulk molding operationsShelf life: 12 months in original packaging at 5–25 °C

Clean packaging for contamination-sensitive production environments

Why Choose Silico® Medical Grade LSR ?

Silico® is a trusted brand in high-performance silicone solutions. With over a decade of experience in medical-grade elastomer innovation, we offer:

✅ Certified and validated raw materials

✅ Technical support for molding, design, and compliance

✅ Fast delivery and stable supply chain

✅ R&D support for custom medical formulations

Silico® offers full technical documentation and compliance certificates upon request, including TDS, MSDS, ISO/USP reports, and processing guides.

📩 Contact us today for technical data sheets (TDS), safety data sheets (SDS), samples, or custom formulation support.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.