Silico®-PV401 Phenyl Vinyl Silicone Oil

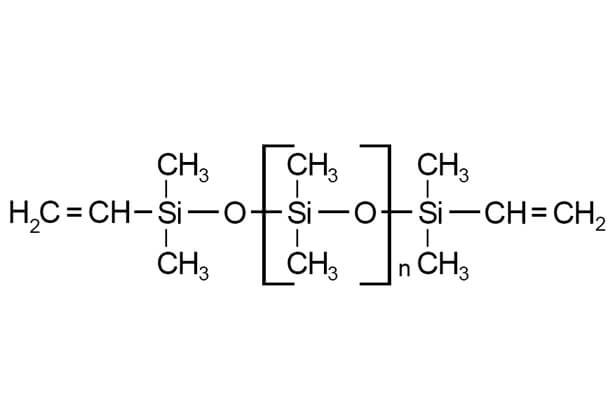

Vinyl-terminated phenylmethylsiloxane silicone oil (CAS: 67762-94-1) is used in addition-curing silicone rubber. It enhances temperature, radiation, and aging resistance. Ideal for LED packaging, potting, sealing, and coating in electronics, it offers high refractive index, UV resistance, and no yellowing. It also provides strong solvent and water resistance. Structure:

(CH₂=CH₂)(CH₃)₂SiO[(CH₃)₂SiO]ₘ[(C₆H₅)₂SiO]ₙSi(CH₃)₂(CH₂=CH₂)

Features:

Vinyl-terminated phenylmethylsiloxane silicone oil (CAS: 67762-94-1) is primarily used for producing addition-curing liquid silicone rubber. The phenyl functional groups enhance its high and low-temperature resistance, radiation resistance, and aging resistance. At room temperature, it appears as a transparent, viscous liquid.

This silicone oil is widely applied in high-power, high-refractive-index LED packaging, as well as in potting, sealing, bonding, and coating for optoelectronics, electronics, and microelectronics industries. It is also used in high-transparency, high-hardness lenses and other custom applications. The cured film exhibits adjustable hardness, high refractive index, good light transmission, and strong solvent resistance, water resistance, ablation resistance, and radiation resistance.

Additionally, this product offers excellent high-temperature stability, non-tackiness, and exceptional aging resistance, with excellent UV resistance and no yellowing even after long-term use. Its structure is as follows:

(CH₂=CH₂)(CH₃)₂SiO[(CH₃)₂SiO]ₘ[(C₆H₅)₂SiO]ₙSi(CH₃)₂(CH₂=CH₂)

Technical Specifications

| Property | PV401-2500 | PV401-500 |

|---|---|---|

| Appearance | Colorless transparent liquid | Colorless transparent liquid |

| Viscosity (25℃), mPas | 2500±250 | 500±50 |

| Refractive Index (25℃) | 1.420-1.430 | 1.420-1.430 |

| Phenyl Content (mol %) | 10 | 10 |

| Vinyl Content (mol/100g) | 0.0065-0.0075 | 0.0175-0.0185 |

| Volatile Content (150℃, | ≤1.5 | ≤1.5 |

Applications

Mainly used for the production of silicone encapsulants for high-power LEDs, potting, sealing, bonding, and coating in optoelectronics, electronics, and microelectronics industries.

High-transparency, high-hardness lenses.

Other applications to be developed.

Usage and Dosage

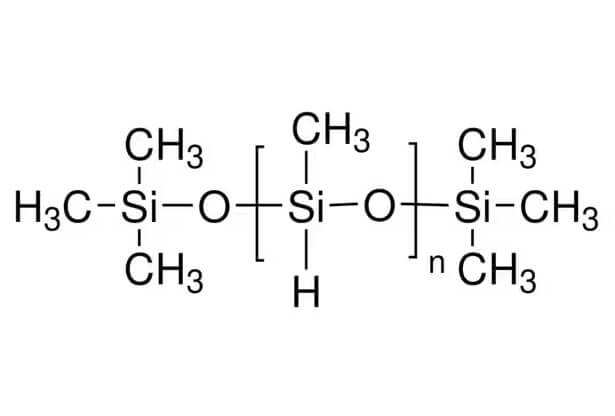

After adding the appropriate crosslinker and catalyst based on vinyl content, mix to form liquid silicone rubber for use.

Precautions

Avoid contact with nitrogen, phosphorus, sulfur, polyvinyl, peroxides, lead, tin, cadmium, and other metal compounds during use, as these can poison silicone rubber catalysts and cause incomplete curing.

Packaging & Storage

Packaging: 25kg, 50kg, 200kg, 1000kg plastic drums.

Storage: Store in a sealed container at room temperature. Keep away from strong acids and bases. Use within 12 months from the date of manufacture if unopened.

Transport: Non-hazardous, transport as general chemical goods.

All technical data provided is based on current knowledge and experience. Users must test product suitability for intended applications.

No warranties are expressed or implied. Silico® assumes no liability for incidental or consequential damages.

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.