Polydimethylsiloxane (PDMS)

| Chemical Name: | Polydimethylsiloxane (PDMS) |

| Alias: | Polydimethylsiloxane, Dimethicone, Dimethylpolysiloxane… |

| Product Category: | Silicone Fluids– Product |

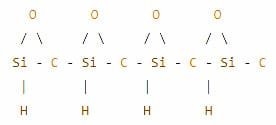

| Structural Formula: |  |

| CAS No.: | 63148-62-9 |

| EINECS: | 204-467-0 |

| Molecular Formula: | (C₂H₆OSi)ₙ (where n represents the number of repeating units) |

| Molecular Weight: | 74.1 g/mol, Varies with the degree of polymerization; |

Polydimethylsiloxane (PDMS) Description

At Silico Organsilicon, we provide premium Polydimethylsiloxane (PDMS), a versatile silicone polymer known for its outstanding properties and wide-ranging applications.

Explore how PDMS can enhance your products. Contact us today for samples, technical support, or to discuss your project needs. We’re dedicated to delivering the best PDMS solutions to help you achieve superior results!

What is PDMS?

Polydimethylsiloxane (PDMS) is a silicone-based polymer known for its unique molecular structure, offering exceptional flexibility, thermal stability, and chemical resistance. These properties make PDMS an ideal solution for a wide range of industries, including cosmetics, healthcare, and manufacturing.

Key Properties

- Chemical Stability: PDMS offers excellent resistance to degradation, ensuring long-term reliability in diverse environments.

- Thermal Resistance: Withstanding temperatures from -50°C to 200°C, PDMS is perfect for high-performance applications.

- Hydrophobic Nature: Its water-repellent properties enhance moisture resistance, ideal for specific formulations.

- Biocompatibility: Safe for medical applications, PDMS is the preferred choice for devices and implants.

Versatile Applications

- Cosmetics & Personal Care: Improve your products with PDMS, acting as an emollient, conditioning agent, and thickener for a luxurious feel and smooth application.

- Medical Devices: Trusted for safety and reliability, PDMS is used in medical devices such as catheters and seals.

- Industrial Uses: Use PDMS as a lubricant to reduce friction and wear in machinery, ensuring efficient performance.

- Food Processing: Utilize PDMS as an effective release agent and anti-foaming agent for optimized food production.

- Electronics: PDMS provides superior insulation and potting solutions, boosting the performance and longevity of electronic devices.

Why Choose Silico’s PDMS?

- Superior Quality: Our PDMS is produced under stringent quality controls, guaranteeing consistent performance and reliability.

- Custom Solutions: We provide tailored PDMS formulations to meet your specific application needs.

- Expert Guidance: Our experienced team is here to help you choose the perfect PDMS product for your requirements.

Packaging Specifications

Jessica G.

Get in touch to Get

- Quick and helpful reply within 8 hours;

- Tailored solutions provided for your project;

- One-stop purchasing service.

Dimethyl Silicone Oil vs. Polydimethylsiloxane (PDMS)

Dimethyl Silicone Oil: A broad term for silicone oils containing dimethylsiloxane units, with varying viscosities.

PDMS: A specific polymer made of repeating dimethylsiloxane units, with a defined structure.

Dimethyl Silicone Oil: Can vary widely in viscosity and application.

PDMS: Known for low viscosity, high thermal stability, and low surface tension.

Dimethyl Silicone Oil: Used in cosmetics, lubricants, and industrial applications.

PDMS: Common in personal care products, medical devices, coatings, and electronics.

In summary, PDMS is a specific type of Dimethyl Silicone Oil, characterized by its polymeric structure and consistent properties.